Ford Fusion: Rear End Sheet Metal Repairs / Inner Quarter Panel and Wheelhouse. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Body and Paint / Body and Paint / Rear End Sheet Metal Repairs / Inner Quarter Panel and Wheelhouse. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spherical Cutter | |

| Air Body Saw | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

| Flexible Foam Repair 3M™ 08463, LORD Fusor® 121 |

- |

Removal

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Remove the following items.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Rocker Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Reposition the carpet and wiring harness away from the work area.

-

-

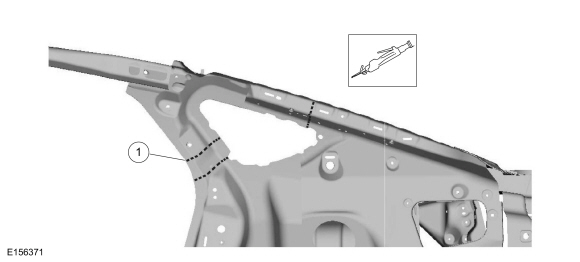

Carefully cut the outer panel only as indicated.

Use the General Equipment: Air Body Saw

-

Carefully cut the outer panel only as indicated.

|

-

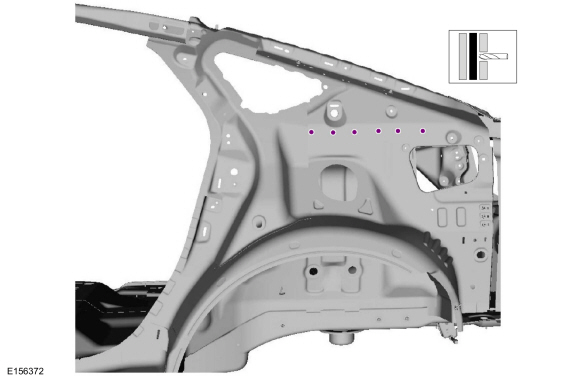

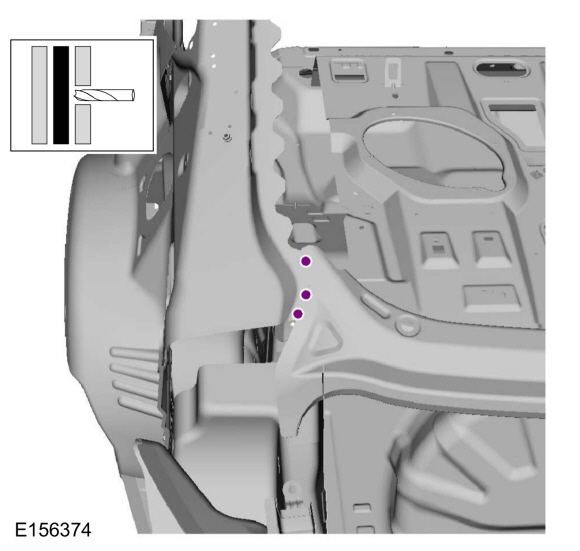

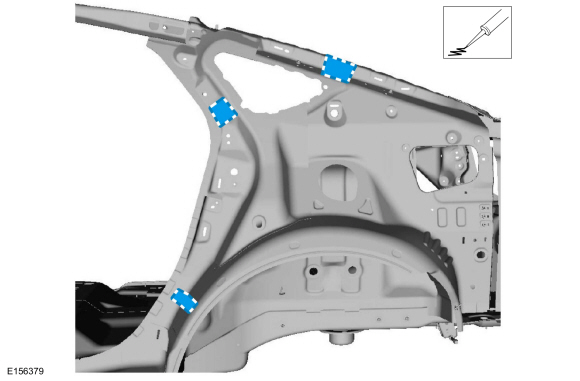

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

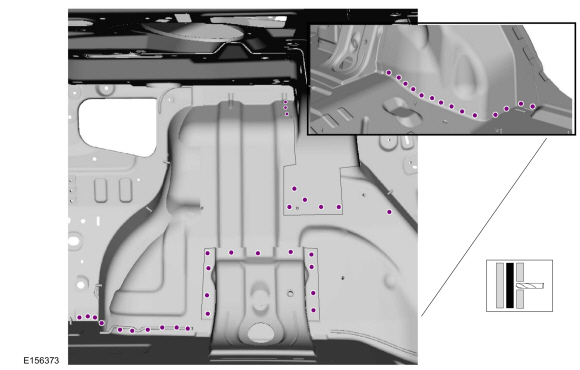

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

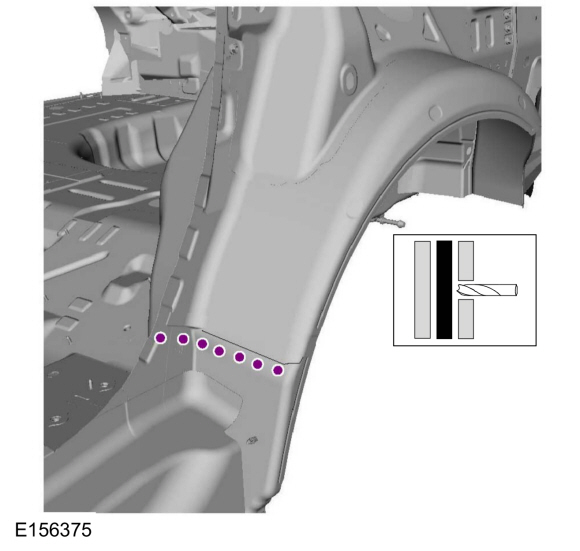

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

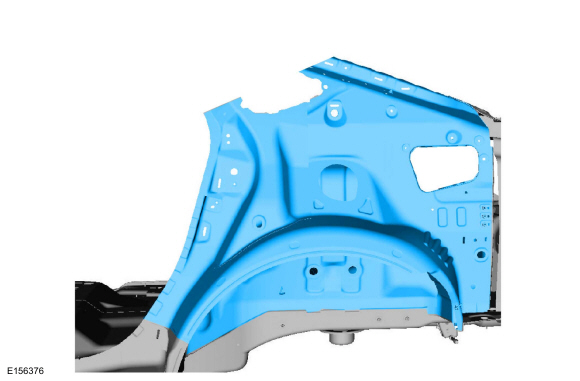

Remove the inner quarter panel and wheelhouse.

|

Installation

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Carefully cut the replacement panel to fit repair.

Use the General Equipment: Spherical Cutter

-

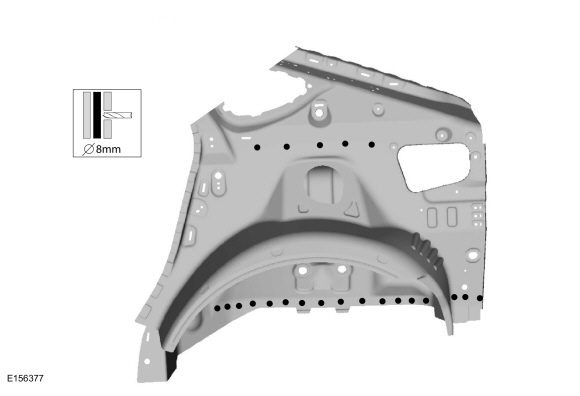

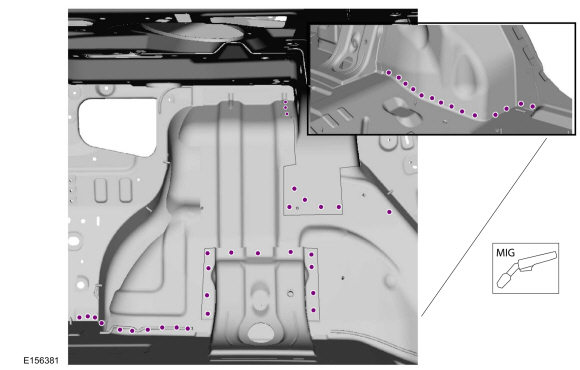

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

|

-

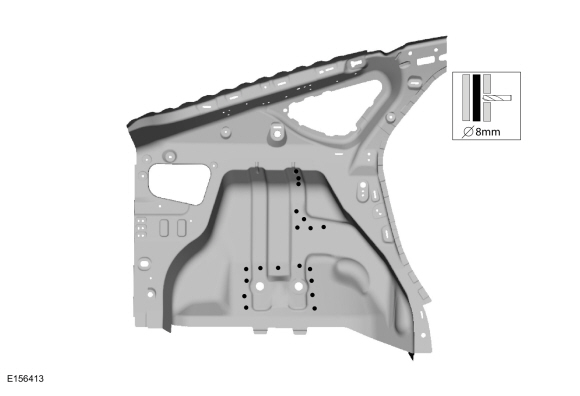

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

|

-

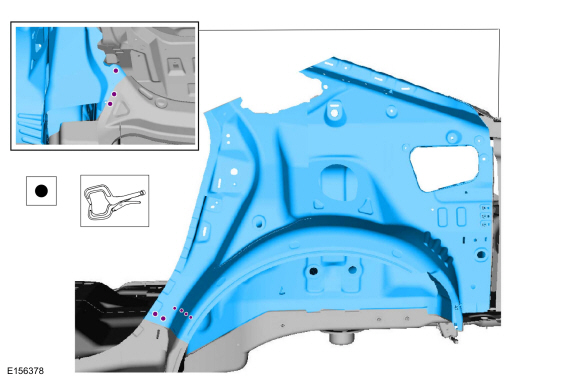

Install the inner quarter panel and wheelhouse, clamp in position and spot weld.

Use the General Equipment: Locking Pliers

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Install the plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

-

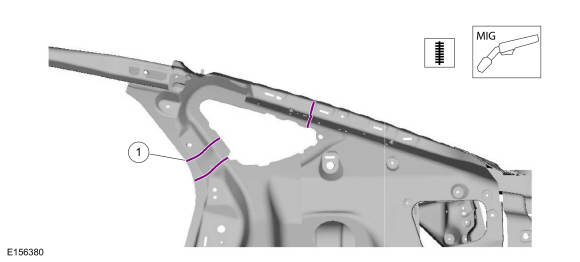

Stitch weld seams.

Use the General Equipment: MIG/MAG Welding Equipment

-

Stitch weld seams.

|

-

Apply NVH material in original locations.

Material: Flexible Foam Repair / 3M™ 08463, LORD Fusor® 121

|

-

Install the LH quarter panel.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Finish all joints using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair area using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition the carpet and the wiring harness.

-

Install the following items.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Rocker Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

Quarter Panel LH. Removal and Installation

Quarter Panel LH. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Hot Air Gun

Air Body Saw

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Flexible Foam Repair3M™ 08463, LORD Fusor® 121

-

Removal

Rem..

Other information:

Ford Fusion 2013–2020 Service Manual: Power Transfer Unit. Diagnosis and Testing

Principles of Operation The AWD system may be referred to as a 4WD system in other service information and owner literature or messages located on the message center. The power transfer unit is a gearbox that is attached to the transmission. The RH intermediate shaft passes through the power transfer unit and engages the differential side gear as in normal FWD applications. The power transfer u..

Ford Fusion 2013–2020 Service Manual: Instrument Panel Cluster (IPC) - System Operation and Component Description. Description and Operation

System Operation System Diagram - Gauges Item Description 1 Base/mid-level 2 High-level 3 Base/mid-level 4 High-level 5 Base/mid-level 6 High-level 7 Base/mid-level 8 High-level 9 AWD 10 Temperature 11 Tachometer 12 HS-CAN1 13 IPC 14 GWM 15 PCM 16 HS-CAN3 ..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Intake Manifold. Removal and Installation

- Under Hood Overview - 1.5L EcoBoost™, 2.0L EcoBoost™, 2.5L, 2.7L EcoBoost™

- Transmission - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

- New on site

- Most important about car

Adjusting the Steering Wheel

WARNING: Do not adjust the steering wheel when your vehicle is moving.

Note: Make sure that you are sitting in the correct position.

Copyright © 2026 www.fofusion2.com