Ford Fusion: Rear End Sheet Metal Repairs / Quarter Panel LH. Removal and Installation

Special Tool(s) /

General Equipment

| Resistance Spotwelding Equipment |

| Hot Air Gun |

| Air Body Saw |

| 8 mm Drill Bit |

| MIG/MAG Welding Equipment |

| Spot Weld Drill Bit |

| Locking Pliers |

Materials

| Name |

Specification |

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

-

Remove the following items.

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

Refer to: Rear Bumper (501-19 Bumpers)

.

Refer to: Rear Lamp Assembly - 4-Door (417-01 Exterior Lighting)

.

Refer to: Fuel Tank Filler Pipe (310-01C Fuel Tank and Lines - 2.5L Duratec (125kW/170PS), Removal and Installation).

Refer to: Rear Seat Cushion (501-10B Rear Seats, Removal and Installation).

-

Reposition carpeting and wiring harness away from the working area.

-

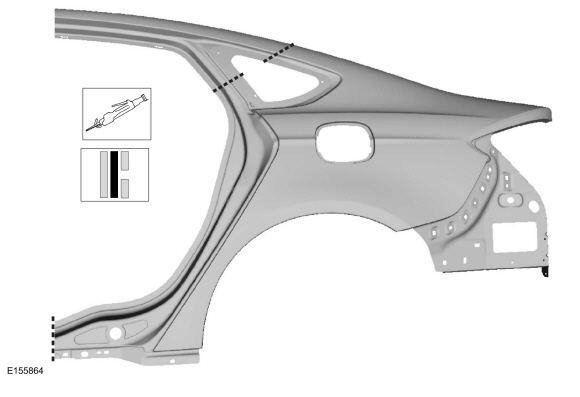

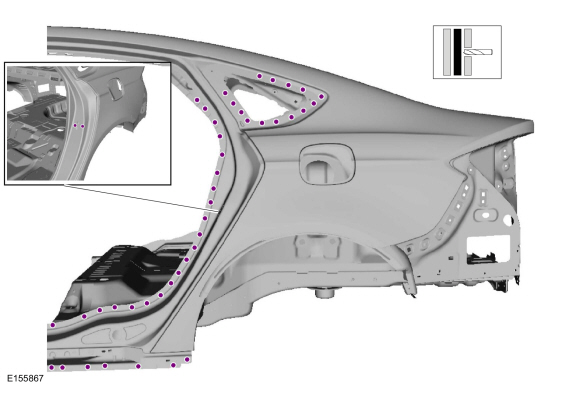

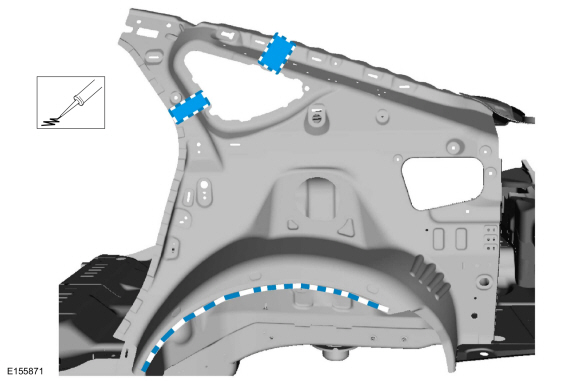

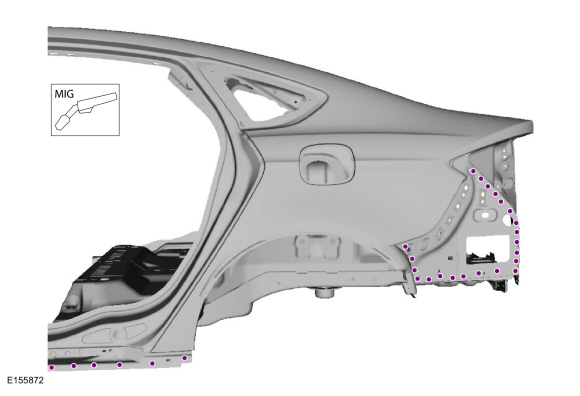

Carefully cut the outer panel only as indicated.

Use the General Equipment: Air Body Saw

-

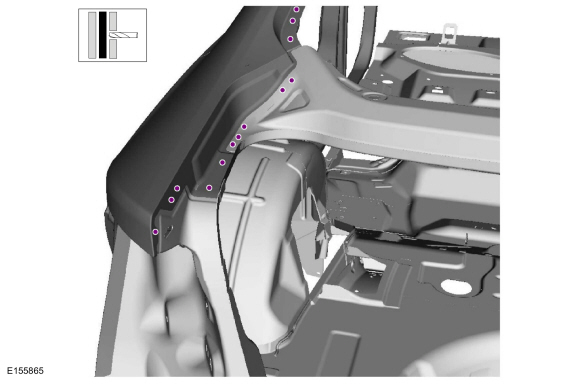

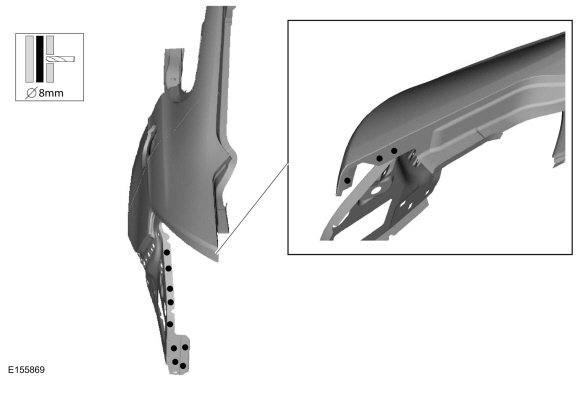

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

-

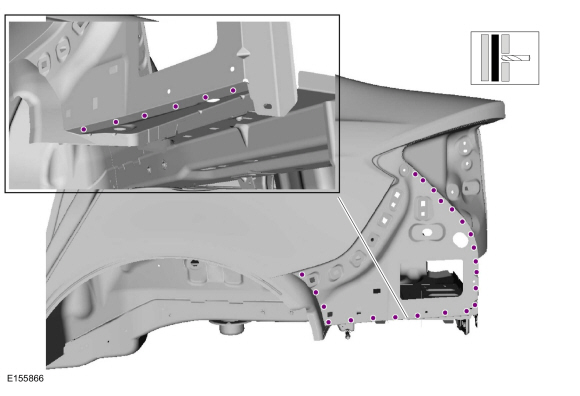

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

-

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

-

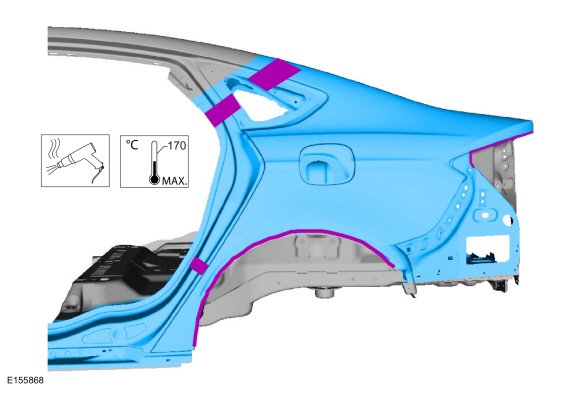

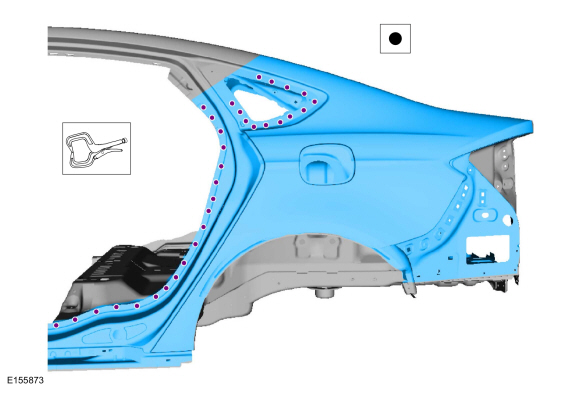

Break the adhesive bond and remove the quarter panel section.

Use the General Equipment: Hot Air Gun

Installation

-

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Cut the replacement panel to fit repair.

-

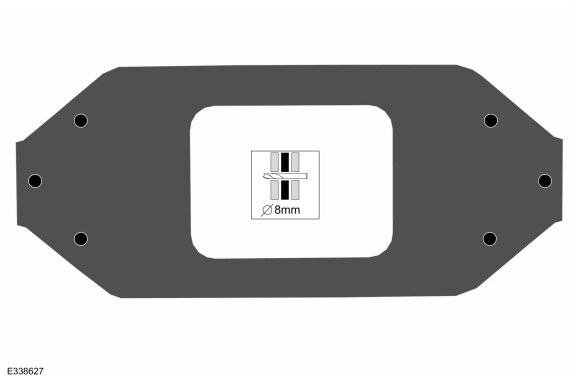

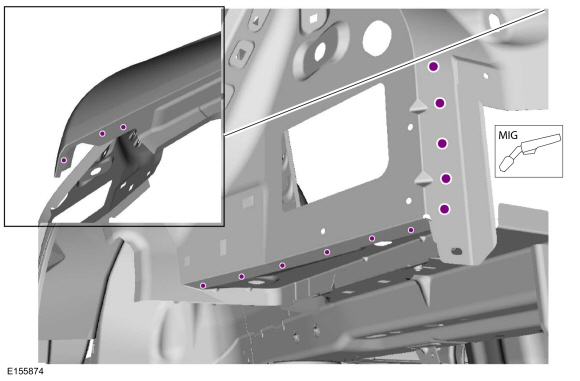

Drill plug weld holes in the replacement stiffener plate.

Use the General Equipment: 8 mm Drill Bit

-

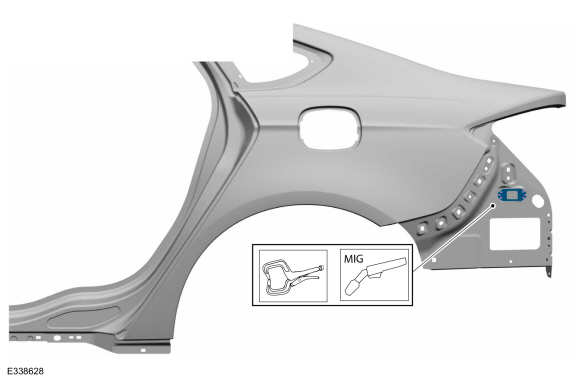

Install, properly position, clamp and weld the replacement stiffener plate.

Use the General Equipment: Locking Pliers

Use the General Equipment: MIG/MAG Welding Equipment

-

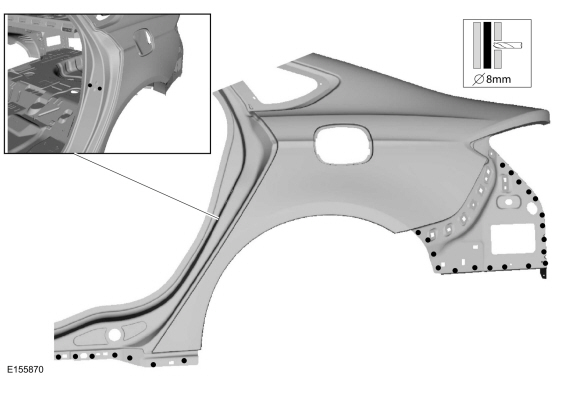

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

-

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

-

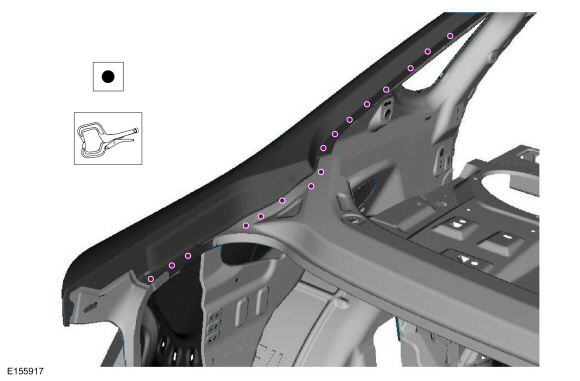

Apply adhesive.

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Install the quarter panel section, clamp in position and spot weld.

Use the General Equipment: Locking Pliers

Use the General Equipment: Resistance Spotwelding Equipment

-

Install the plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Install the plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

-

Install the spot welds.

Use the General Equipment: Resistance Spotwelding Equipment

-

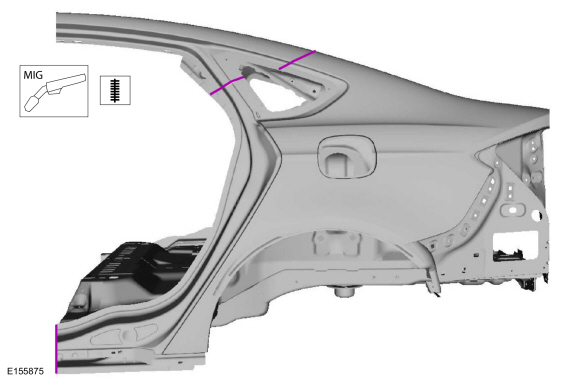

Stitch weld seams as indicated.

Use the General Equipment: MIG/MAG Welding Equipment

-

Metal finish as required using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition carpeting and wiring harness.

-

Install the following items.

Refer to: Rear Seat Cushion (501-10B Rear Seats, Removal and Installation).

Refer to: Fuel Tank Filler Pipe (310-01C Fuel Tank and Lines - 2.5L Duratec (125kW/170PS), Removal and Installation).

Refer to: Rear Lamp Assembly - 4-Door (417-01 Exterior Lighting)

.

Refer to: Rear Bumper (501-19 Bumpers)

.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery..

Other information:

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

NOTE:

Valve guides tend to wear in an hourglass pattern.

The ball gauge can be inserted into the combustion chamber side of the

valve guide, if necessary.

Use a ball gauge to determine the inside diameter of

the valve guides in 2 directions at the top, middle and bottom of the

valve guide.

..

Switching the Front Fog Lamps On or Off

Only switch the front fog lamps on during

reduced visibility.

You can switch the front fog lamps on if

any of the following occur:

You set the lighting control to the

parking lamps position.

You set the lighting control to the

headlamps position.

You set the lighting control to the

autolamps position and the headlamps

are on.

The front fog l..

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Rear Bumper Mounting bracket. Removal and Installation

Rear Bumper Mounting bracket. Removal and Installation