Ford Fusion: Engine System - General Information / Cylinder Head Distortion. General Procedures

Ford Fusion 2013–2020 Service Manual / Powertrain / Engine / Engine System - General Information / Cylinder Head Distortion. General Procedures

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

NOTE: Make sure all cylinder head surfaces are clear of any gasket material, silicone sealant, oil and coolant. The cylinder head surface must be clean and dry before running a flatness check.

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

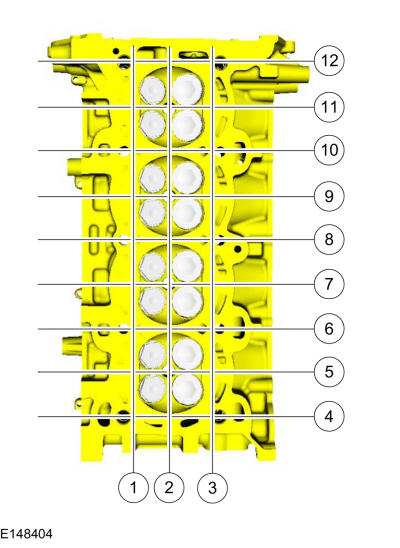

Using a Straightedge and a Feeler Gauge Set, inspect the cylinder head for flatness in the sequence shown.

Use the General Equipment: Feeler Gauge

|

Cylinder Bore Taper. General Procedures

Cylinder Bore Taper. General Procedures

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated...

Exhaust Manifold Cleaning and Inspection. General Procedures

Exhaust Manifold Cleaning and Inspection. General Procedures

Special Tool(s) /

General Equipment

Feeler Gauge

Cleaning

Clean the exhaust manifold using a suitable solvent. Use

a plastic scraping tool to clean the gasket sealing surfaces...

Other information:

Ford Fusion 2013–2020 Owners Manual: Hints on Controlling the Interior Climate - Vehicles With: Automatic Temperature Control

General Hints Note: Prolonged use of recirculated air may cause the windows to fog up. Note: You may feel a small amount of air from the footwell air vents regardless of the air distribution setting. Note: To reduce humidity build-up inside your vehicle, do not drive with the system switched off or with recirculated air always switched on...

Ford Fusion 2013–2020 Service Manual: Warning Chimes - System Operation and Component Description. Description and Operation

System Operation System Diagram Network Message Chart Module Network Input Messages - IPC Broadcast Message Originating Module Message Purpose Adaptive cruise control stop mode Cruise Control Module (C-CM) Input used to control the adaptive cruise control warning chime...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Engine

- Electrical

- Traction Control

- New on site

- Most important about car

Direction Indicators. Interior Lamps

Direction Indicators

Push the lever up or down to use the direction indicators.

Copyright © 2026 www.fofusion2.com