Ford Fusion: Roof Sheet Metal Repairs / Roof Panel. Removal and Installation

Special Tool(s) /

General Equipment

| Resistance Spotwelding Equipment |

| Spherical Cutter |

| Grinder |

| Knife |

| Spot Weld Drill Bit |

| Locking Pliers |

Materials

| Name |

Specification |

Metal Bonding Adhesive

TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B |

-

|

Seam Sealer

TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

-

|

Flexible Foam Repair

3M™ 08463, LORD Fusor® 121 |

-

|

Removal

-

NOTICE:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

NOTICE:

Adequately protect all glass, exterior finish and

interior trim from contamination during entire repair procedure.

Remove the following items:

-

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Depower the SRS.

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the headliner.

Refer to: Headliner (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Remove the side air curtains.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Remove the windshield and rear window glass.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

-

Remove the audio unit antenna.

Refer to: Audio Unit Antenna (415-00 Information and

Entertainment System - General Information - Vehicles With:

AM/FM/CD/SYNC/Sony Audio System)

.

Refer to: Audio Unit Antenna (415-00 Information and

Entertainment System - General Information - Vehicles With:

AM/FM/CD/SYNC)

.

Refer to: Audio Unit Antenna (415-00 Information and Entertainment System - General Information - Vehicles With: SYNC 3, Removal and Installation).

-

NOTE:

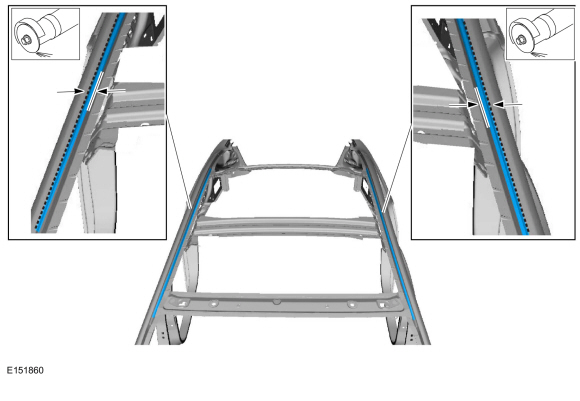

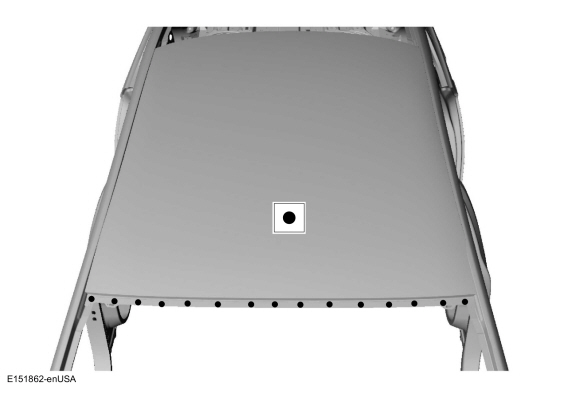

Cut the outer panel only.

Carefully cut the the inner edge of the roof panel ditch on each side.

Use the General Equipment: Spherical Cutter

-

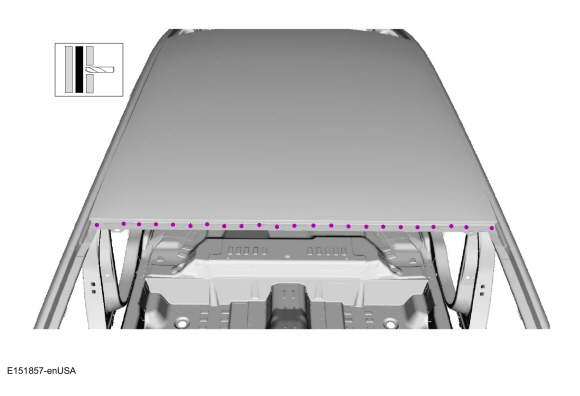

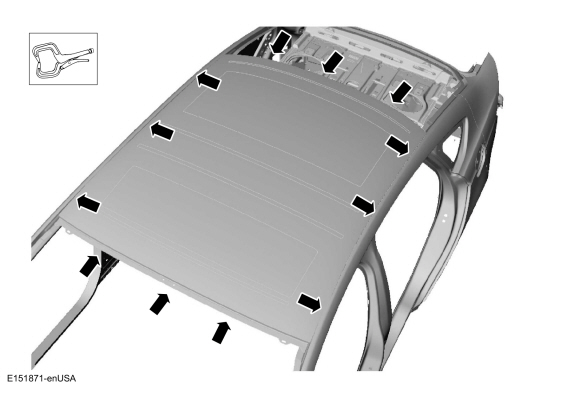

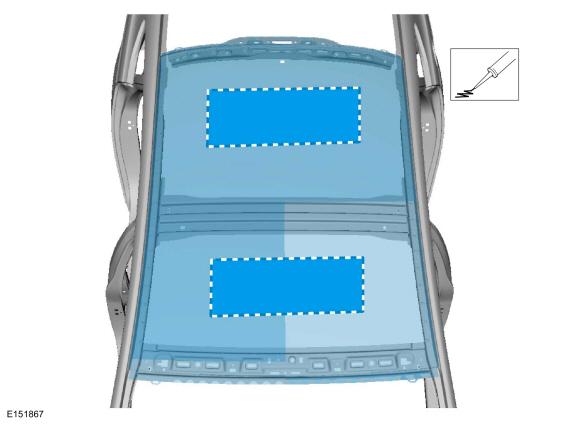

Remove the spot welds at the windshield opening.

Use the General Equipment: Spot Weld Drill Bit

-

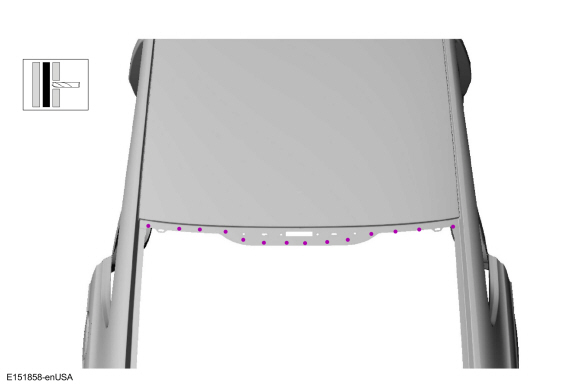

Remove the spot welds at the rear window glass opening area.

Use the General Equipment: Spot Weld Drill Bit

-

NOTE:

Leave as much NVH foam as possible intact on the roof bows.

Separate the roof panel from the roof reinforcements.

Use the General Equipment: Knife

-

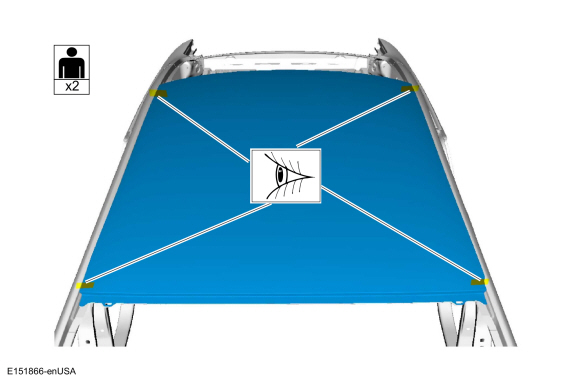

With the help of an assistant, remove the roof panel.

-

Remove the remaining portion of the outer roof panel flange.

Use the General Equipment: Grinder

-

Clean area and remove any remaining residue.

Installation

-

Abrade flange roof panel mating area.

Use the General Equipment: Grinder

-

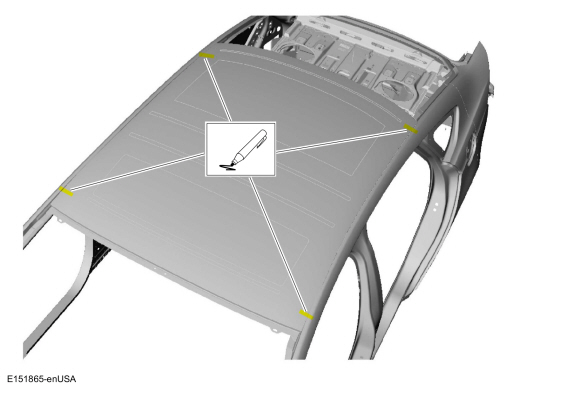

With the help of an assistant, install the roof panel to the vehicle.

-

Properly align and index mark the roof panel to the vehicle.

-

With the help of an assistant, remove the roof panel.

-

Abrade flange mating area of replacement roof panel.

-

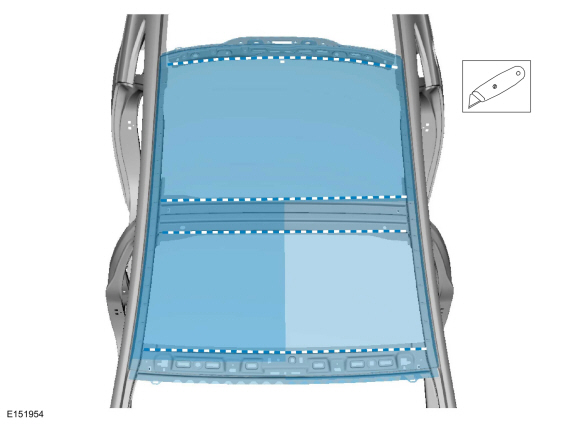

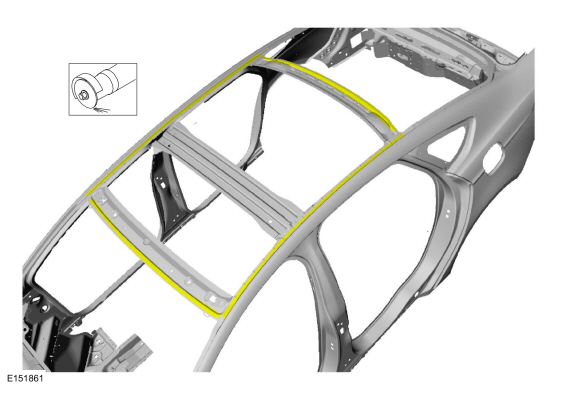

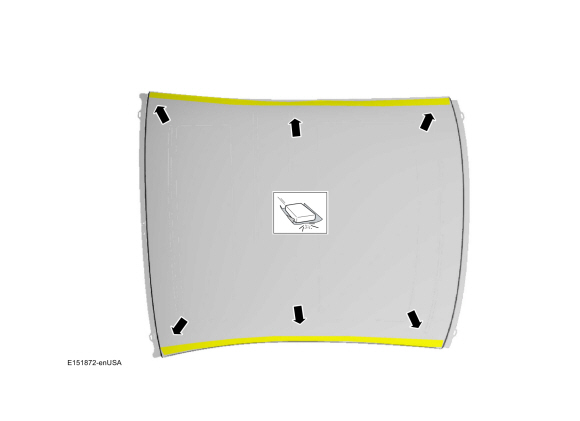

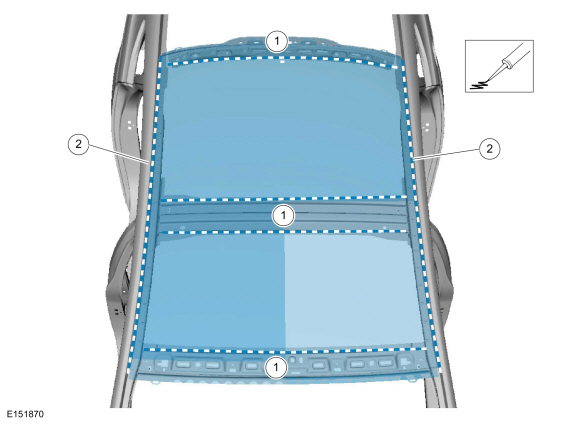

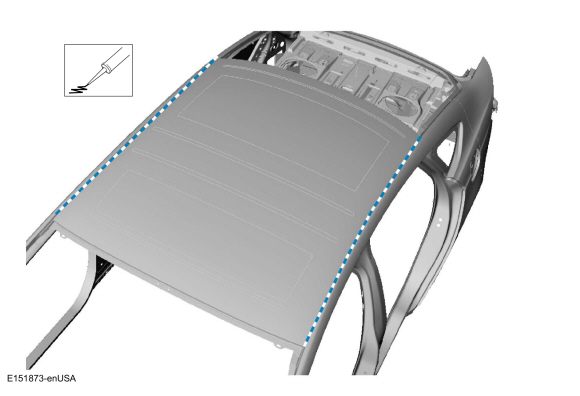

Apply adhesive and sealant as indicated.

-

Flexible foam sealant.

Material: Flexible Foam Repair

/ 3M™ 08463, LORD Fusor® 121

-

Metal bonding adhesive

Material: Metal Bonding Adhesive

/ TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B

-

NOTE:

Do not lift the panel from the body once installed.

If the panel requires repositioning, slide the panel to correct

alignment location.

NOTE:

To assure complete bonding, check all locations for

full adhesive contact. Add additional adhesive as necessary.

With the help of an assistant, install and align the roof outer panel.

-

Tightly clamp (without damaging) the roof outer panel.

Use the General Equipment: Locking Pliers

-

Resistance spot weld the windshield opening flange.

Use the General Equipment: Resistance Spotwelding Equipment

-

Resistance spot weld at the rear window glass opening area.

Use the General Equipment: Resistance Spotwelding Equipment

-

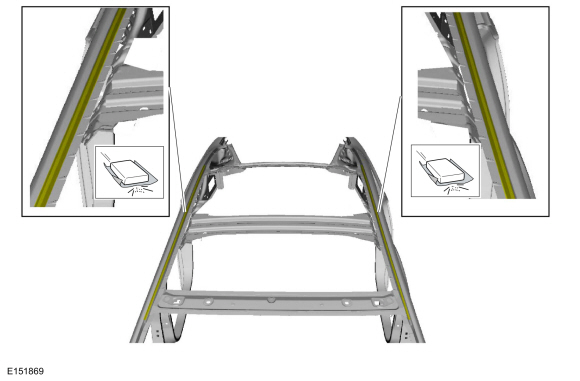

Install NVH pads.

-

Apply seam sealer.

Material: Seam Sealer

/ TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the roof panel using a Ford approved paint system.

-

Install the following items:

-

Install the audio unit antenna.

Refer to: Audio Unit Antenna (415-00 Information and

Entertainment System - General Information - Vehicles With:

AM/FM/CD/SYNC/Sony Audio System)

.

Refer to: Audio Unit Antenna (415-00 Information and

Entertainment System - General Information - Vehicles With:

AM/FM/CD/SYNC)

.

Refer to: Audio Unit Antenna (415-00 Information and Entertainment System - General Information - Vehicles With: SYNC 3, Removal and Installation).

-

Install the fixed glass.

Refer to: Fixed Glass (501-11 Glass, Frames and Mechanisms, General Procedures).

-

Install the side air curtains.

Refer to: Side Curtain Airbag (501-20B Supplemental Restraint System, Removal and Installation).

-

Install the headliner.

Refer to: Headliner (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

Repower the SRS.

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery...

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Spherical Cutter

Grinder

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B

-

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTICE:

Before beginning any servic..

Other information:

General Specifications

Item

Specification

Normal engine cranking speed (Average)

200-300 Revolutions Per Minute (RPM)

Starting circuit maximum voltage drop (Engine at normal operating temperature) (Average)

0.5 volt

Starter motor maximum load current draw

900 amps

Starter motor no-load current draw (Avera..

Adjustment

WARNING:

Before beginning any service procedure in this section,

refer to Safety Warnings in section 100-00 General Information. Failure

to follow this instruction may result in serious personal injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

On both sides.

Detach the top portion of the roof..

Roof Front Frame. Removal and Installation

Roof Front Frame. Removal and Installation Roof Panel - Vehicles With: Roof Opening Panel. Removal and Installation

Roof Panel - Vehicles With: Roof Opening Panel. Removal and Installation