Ford Fusion: Electronic Engine Controls - 1.5L EcoBoost (118kW/160PS) – I4 / Catalyst Monitor Sensor. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Powertrain / Engine / Electronic Engine Controls - 1.5L EcoBoost (118kW/160PS) – I4 / Catalyst Monitor Sensor. Removal and Installation

Special Tool(s) / General Equipment

|

303-476

(T94P-9472-A)

Socket, Exhaust Gas Oxygen Sensor TKIT-1994-LM/M TKIT-1994-F TKIT-1994-FLM/FM |

Materials

| Name | Specification |

|---|---|

| Motorcraft® High Temperature Nickel Anti-Seize Lubricant XL-2 |

- |

| Motorcraft® Penetrating and Lock Lubricant XL-1 |

- |

Removal

-

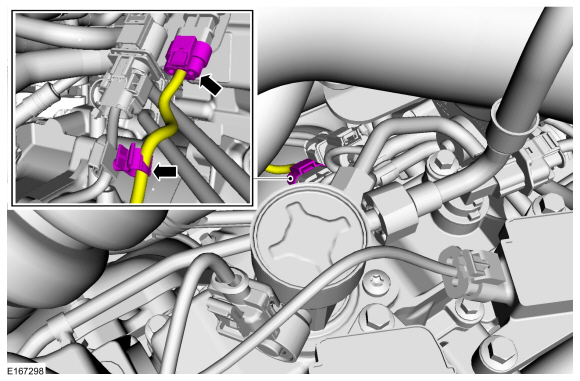

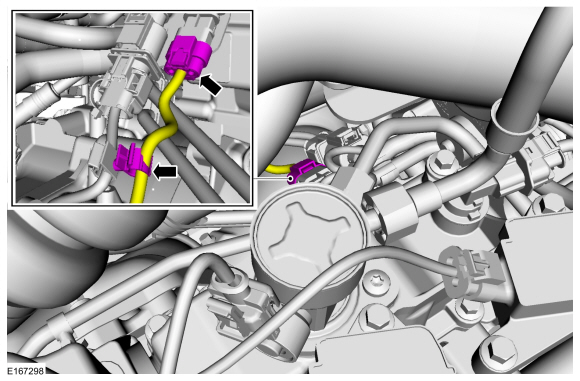

Disconnect the catalyst monitor sensor electrical connector and detach the wiring harness retainer.

|

-

With the vehicle in N, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

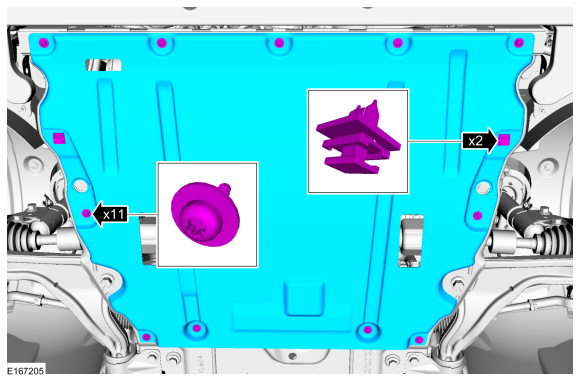

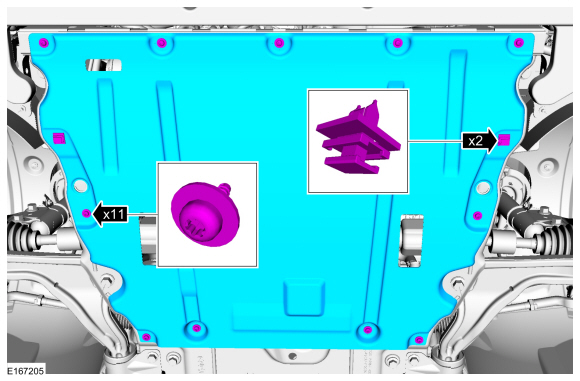

Remove the retainers and the engine undershield.

|

-

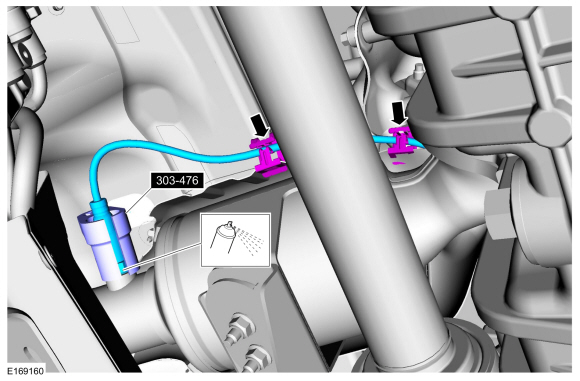

Remove the catalyst monitor sensor and detach the wiring harness retainers.

Use Special Service Tool: 303-476 (T94P-9472-A) Socket, Exhaust Gas Oxygen Sensor.

Material: Motorcraft® Penetrating and Lock Lubricant / XL-1

|

Installation

-

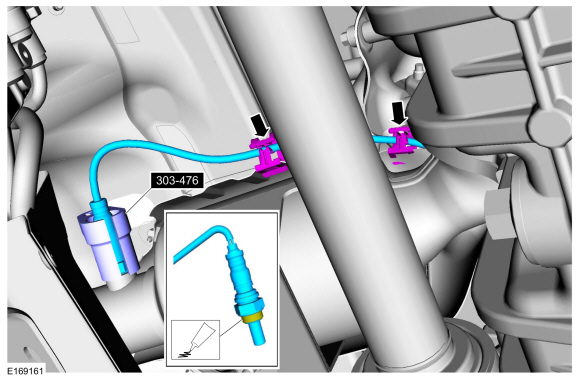

Calculate the correct torque wrench setting for the

following torque. Refer to Torque Wrench Adapter Formula in the Apex.

Install the catalyst monitor sensor and attach the wiring harness retainers.

Use Special Service Tool: 303-476 (T94P-9472-A) Socket, Exhaust Gas Oxygen Sensor.

Material: Motorcraft® High Temperature Nickel Anti-Seize Lubricant / XL-2

Torque: 35 lb.ft (48 Nm)

|

-

Install the engine undershield and the retainers.

|

-

Connect the catalyst monitor sensor electrical connector and attach the wiring harness retainer.

|

Camshaft Position (CMP) Sensor RH. Removal and Installation

Camshaft Position (CMP) Sensor RH. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

Remove the engine appearance cover.

Disconnect the CMP sensor electrical connector, remove the retainer and the CMP sensor...

Charge Air Cooler Coolant Temperature (CACCT) Sensor. Removal and Installation

Charge Air Cooler Coolant Temperature (CACCT) Sensor. Removal and Installation

Materials

Name

Specification

Motorcraft® Orange Prediluted Antifreeze/CoolantVC-3DIL-B

WSS-M97B44-D2

Removal

NOTE:

Removal steps in this procedure may contain installation details...

Other information:

Ford Fusion 2013–2020 Service Manual: Parking Brake - System Operation and Component Description. Description and Operation

System Operation System Diagram Network Message Chart NOTE: The TCM is also known as the Secondary On Board Diagnostic Module C (SOBDMC). Module Network Input Messages - ABS Module Broadcast Message Originating Module Message Purpose Accelerator pedal position PCM This message is sent to the GWM..

Ford Fusion 2013–2020 Service Manual: Staged Unlock Programming. General Procedures

Programming WARNING: Before beginning any service procedure in this manual, refer to health and safety warnings in section 100-00 General Information. Failure to follow this instruction may result in serious personal injury. Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation). With the ignition in OFF, press the lock ..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Front Controls Interface Module (FCIM). Removal and Installation

- Automatic Transmission Fluid Check - 1.5L EcoBoost™/2.0L EcoBoost™/2.5L. Automatic Transmission Fluid Check - 2.7L EcoBoost™

- Transmission - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

- New on site

- Most important about car

Power Door Locks

The power door lock control is on the driver and front passenger door panels.

Copyright © 2026 www.fofusion2.com