Ford Fusion: Side Panel Sheet Metal Repairs / B-Pillar and Reinforcement. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Body and Paint / Body and Paint / Side Panel Sheet Metal Repairs / B-Pillar and Reinforcement. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

| Flexible Foam Repair 3M™ 08463, LORD Fusor® 121 |

- |

Removal

-

Restore vehicle to pre-accident dimensions.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items:

-

Refer to: B-Pillar Outer Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Refer to: B-Pillar Outer Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

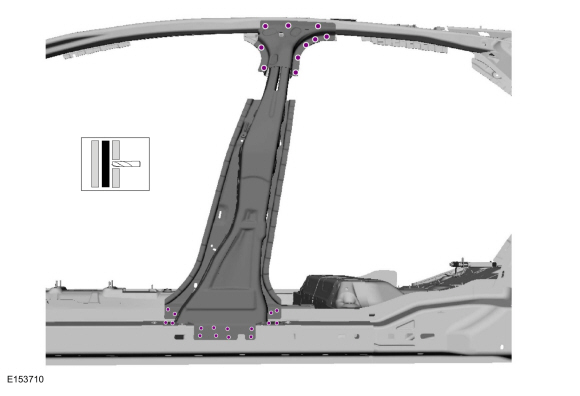

Drill out the spot welds from the B-pillar inner panel.

Use the General Equipment: Spot Weld Drill Bit

|

-

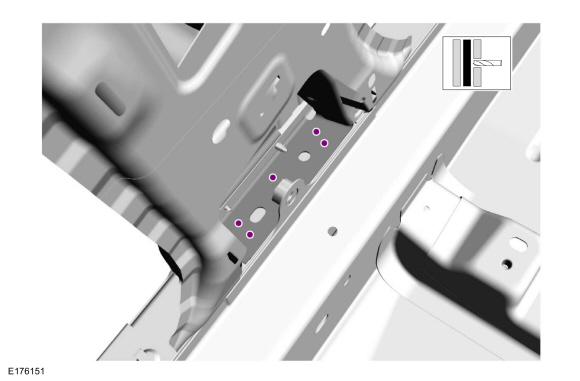

NOTE: Remove NVH foam to access lower reinforcement.

To facilitate access to lower reinforcement spot welds, it is recommended to cut and remove the old B-pillar reinforcement 50-75 mm above the rocker panel.

Drill out the spot welds from the lower reinforcement.

Use the General Equipment: Spot Weld Drill Bit

|

-

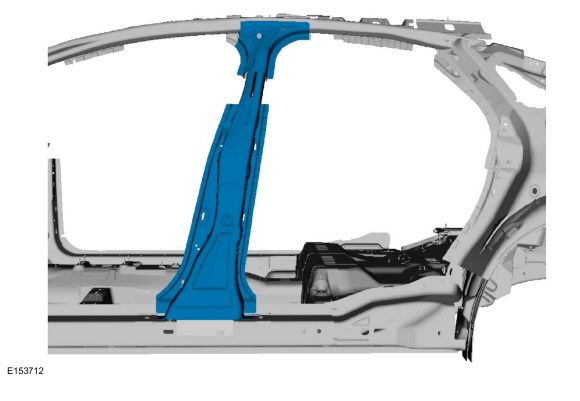

Remove the B-pillar reinforcement.

|

Installation

-

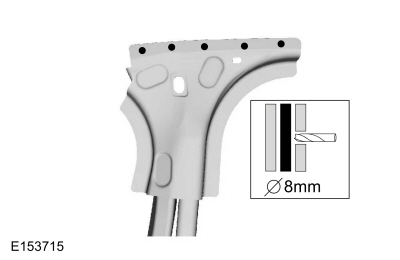

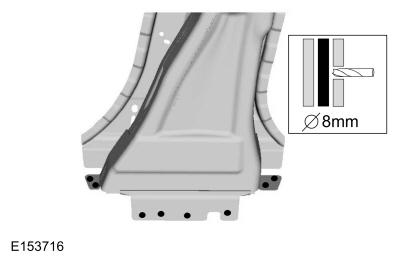

Drill plug weld holes in the upper portion of the replacement panel.

Use the General Equipment: 8 mm Drill Bit

|

-

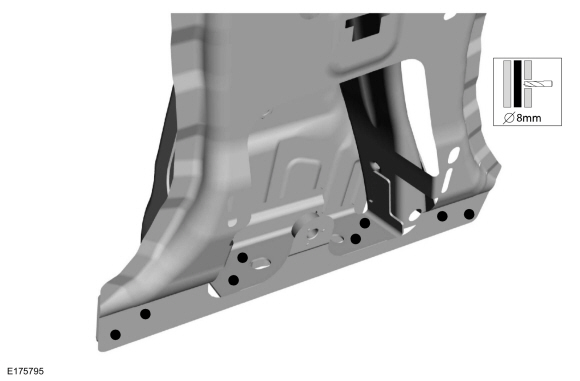

Drill plug weld holes in the lower portion of the replacement panel.

Use the General Equipment: 8 mm Drill Bit

|

-

Drill 8 mm plug weld holes.

Use the General Equipment: 8 mm Drill Bit

|

-

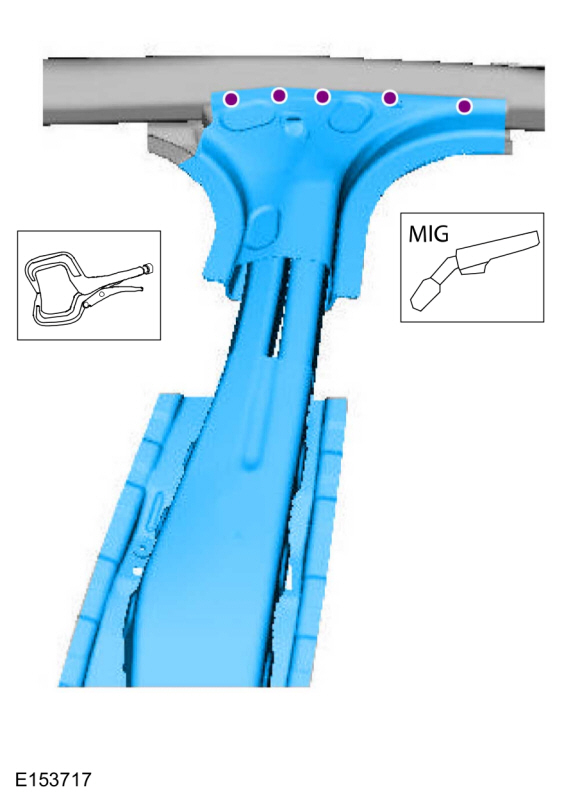

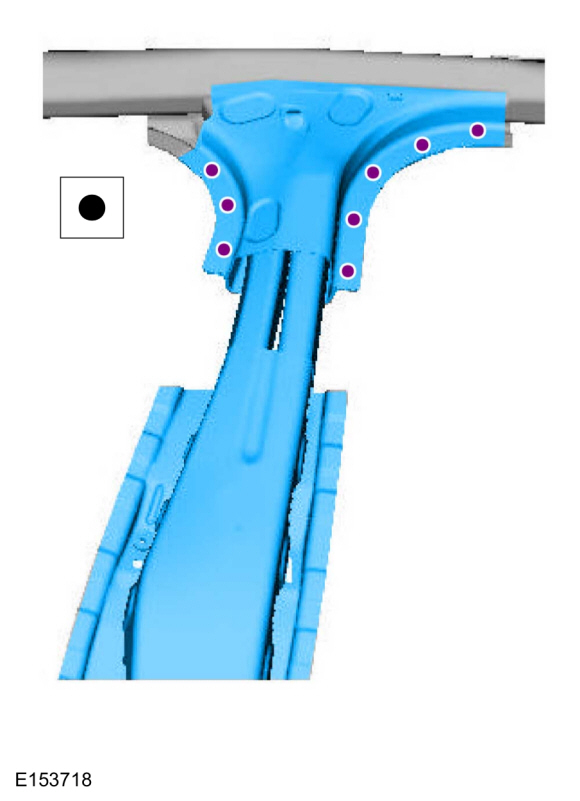

Install, clamp and plug weld the upper portion of the B-pillar inner panel.

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Locking Pliers

|

-

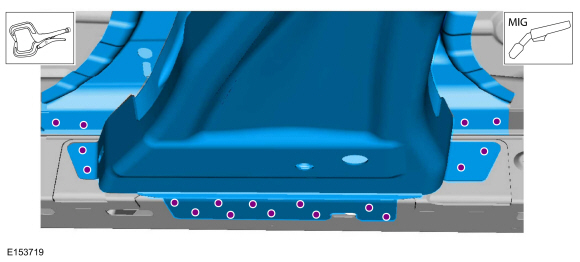

Install, clamp and plug weld the lower portion of the B-pillar inner panel.

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Locking Pliers

|

-

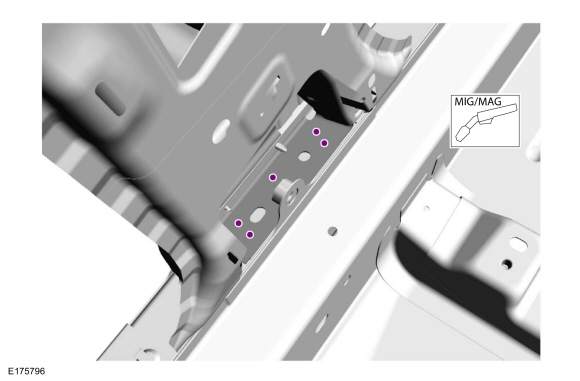

Plug weld the lower reinforcement.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Finish the repair area using typical metal finishing procedures.

-

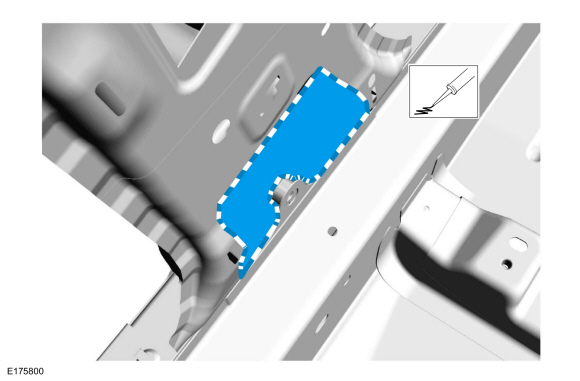

Apply foam to cavity as indicated.

Material: Flexible Foam Repair / 3M™ 08463, LORD Fusor® 121

|

-

Spot weld the upper portion of the B-pillar inner panel.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Finish the repair area using typical metal finishing procedures.

-

Sand and prime repair area using a Ford approved paint system.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair area using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the following items:

-

Refer to: B-Pillar Outer Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

-

Refer to: B-Pillar Outer Panel (501-29 Side Panel Sheet Metal Repairs, Removal and Installation).

A-Pillar Outer Panel Section and Reinforcement. Removal and Installation

A-Pillar Outer Panel Section and Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Hot Air Gun

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Flexible Foam Repair3M™ 08463, LORD Fusor® 121

-

Removal

WARNING:

Be..

Other information:

Ford Fusion 2013–2020 Service Manual: Power Roof Opening Panel Initialization. General Procedures

Initialization WARNING: Keep objects and body parts clear of the glass panel when carrying out the initialization procedure. During the initialization procedure, the glass panel closes with high force and cannot detect objects in its path. Failure to follow this instruction may result in serious personal injury. NOTE: A new roof opening panel motor must be initialized after i..

Ford Fusion 2013–2020 Service Manual: Turbine Shaft Speed (TSS) Sensor. Removal and Installation

Removal Remove the air cleaner. Refer to: Air Cleaner (303-12A Intake Air Distribution and Filtering - 1.5L EcoBoost (118kW/160PS) – I4, Removal and Installation). Refer to: Air Cleaner (303-12B Intake Air Distribution and Filtering - 2.0L EcoBoost (184kW/250PS) – MI4, Removal and Installation). Refer to: Air Cleaner (303-12C Intake Air Distribution and Filtering - 2.5L Duratec (12..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Electrical

- Pre-Collision Assist (IF EQUIPPED)

- Automatic Transmission Fluid Check - 1.5L EcoBoost™/2.0L EcoBoost™/2.5L. Automatic Transmission Fluid Check - 2.7L EcoBoost™

- New on site

- Most important about car

Direction Indicators. Interior Lamps

Direction Indicators

Push the lever up or down to use the direction indicators.

Copyright © 2026 www.fofusion2.com