Ford Fusion: Climate Control System - General Information / Air Conditioning (A/C) Compressor Outlet Line - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Electrical / Climate Control System / Climate Control System - General Information / Air Conditioning (A/C) Compressor Outlet Line - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

Removal

NOTICE: During the removal or installation of components, cap, tape or otherwise appropriately protect all openings and tubes/fittings to prevent the ingress of dirt or other contamination. Remove caps, tape and other protective materials prior to installation.

NOTE: Removal steps in this procedure may contain installation details.

-

Recover the refrigerant. Refer to the appropriate Recovery procedure in Group 412.

-

With the vehicle in N, position it on a hoist.

Refer to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

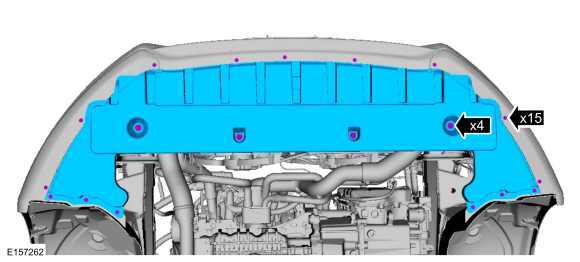

Remove the bolts and the radiator undershield.

|

-

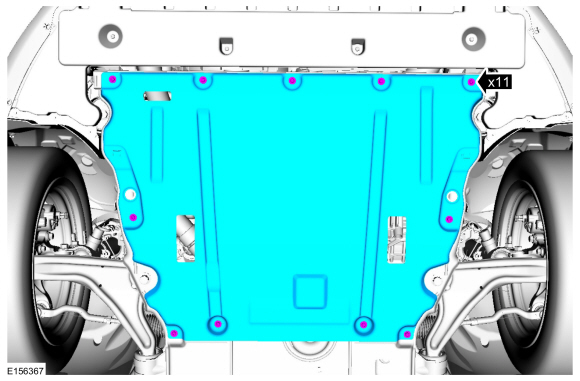

Remove the retainers and the engine undershield.

|

-

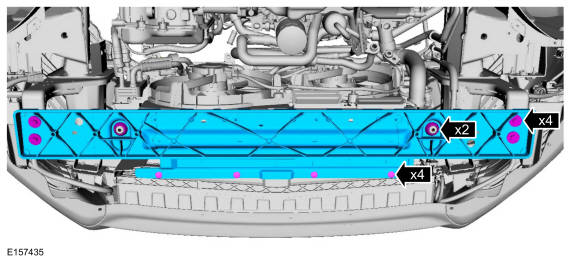

Remove the retainers, bolts, insulators and the cooling module support panel.

Torque: 18 lb.ft (24 Nm)

|

-

NOTICE: Make sure that all openings are sealed.

-

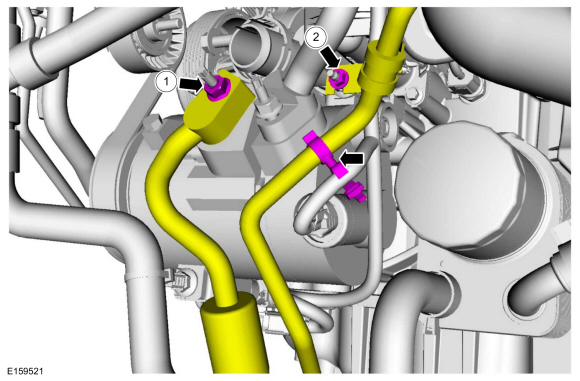

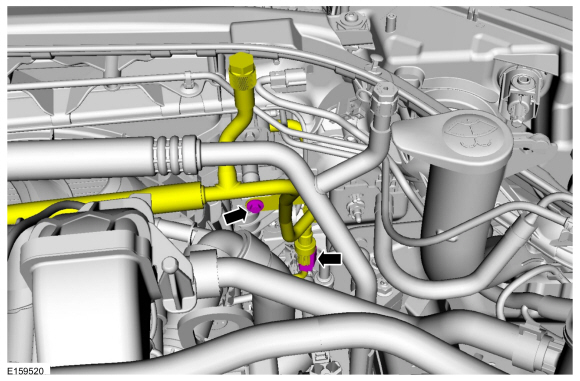

Remove the A/C compressor outlet line nut.

Torque: 133 lb.in (15 Nm)

-

Detach the wiring harness retainer, remove the nut and position the A/C compressor outet line aside. Discard the O-ring seal and gasket seal.

Torque: 18 lb.ft (25 Nm)

-

Make sure to cover any open ports to prevent debris from entering the system.

-

Remove the A/C compressor outlet line nut.

|

-

Disconnect the A/C pressure transducer electrical connector, remove the bracket bolt and position aside the bracket.

Torque: 62 lb.in (7 Nm)

|

-

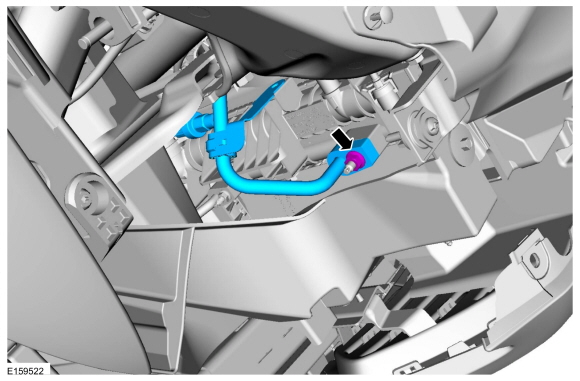

NOTICE: Make sure that all openings are sealed.

Remove the A/C compressor outlet line nut, disconnect the fitting and remove the A/C compressor outlet line. Discard the O-ring seal and gasket seal.

-

Make sure to cover any open ports to prevent debris from entering the system.

Torque: 133 lb.in (15 Nm)

-

Make sure to cover any open ports to prevent debris from entering the system.

|

Installation

-

To install, reverse the removal procedure.

-

NOTICE: Only use the specified material to lubricate the seals.

Install and lubricate new O-ring seals. Refer to the appropriate Specifications in Group 412.

-

Lubricate the refrigerant system with the correct amount

of clean PAG oil. Refer to the appropriate Refrigerant Oil Adding

procedure in Group 412.

Air Conditioning (A/C) Compressor Inlet Line - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

Air Conditioning (A/C) Compressor Inlet Line - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

Removal

NOTICE:

During the removal or installation of components, cap, tape

or otherwise appropriately protect all openings and tubes/fittings to

prevent the ingress of dirt or other contamination...

Air Conditioning (A/C) Pressure Transducer. Removal and Installation

Air Conditioning (A/C) Pressure Transducer. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details .

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information...

Other information:

Ford Fusion 2013–2020 Owners Manual: General Information. Keyless Starting

General Information WARNING: Extended idling at high engine speeds can produce very high temperatures in the engine and exhaust system, creating the risk of fire or other damage. WARNING: Do not park, idle or drive your vehicle on dry grass or other dry ground cover...

Ford Fusion 2013–2020 Service Manual: Evaporator Inlet and Outlet Manifold. Removal and Installation

Removal NOTICE: During the removal or installation of components, cap, tape or otherwise appropriately protect all openings and tubes/fittings to prevent the ingress of dirt or other contamination. Remove caps, tape and other protective materials prior to installation...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Steering Column Control Module (SCCM). Removal and Installation

- Body Control Module (BCM). Removal and Installation

- Main Control Valve Body. Removal and Installation

- New on site

- Most important about car

Direction Indicators. Interior Lamps

Direction Indicators

Push the lever up or down to use the direction indicators.

Copyright © 2025 www.fofusion2.com