Ford Fusion: Side Panel Sheet Metal Repairs / Rocker Panel. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Body and Paint / Body and Paint / Side Panel Sheet Metal Repairs / Rocker Panel. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Hot Air Gun | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

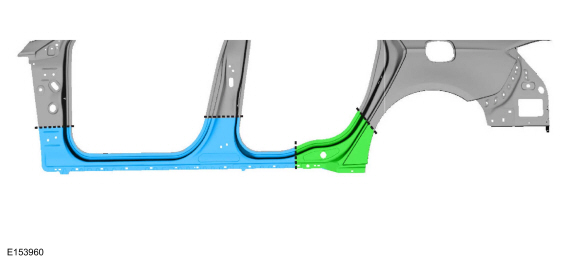

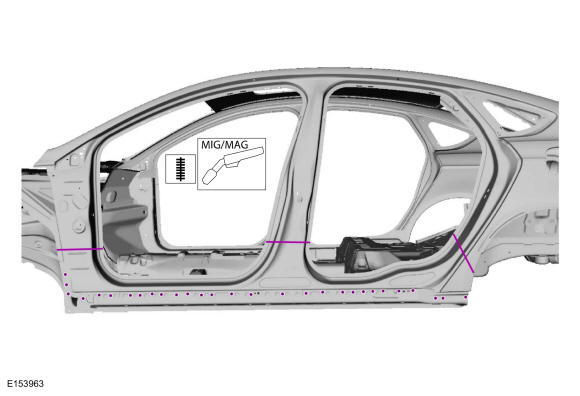

NOTE: Cut lines depend on damage and service part.

Possible cutlines depending on damage.

|

-

Restore vehicle to pre-accident dimensions.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Depower the SRS.

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

-

Remove the following items:

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

Refer to: Rocker Panel Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Refer to: Seatbelt Retractor and Pretensioner (501-20A Seatbelt Systems, Removal and Installation).

Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Front Door (501-03 Body Closures, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

-

Reposition the carpet and the wiring harness away from the repair area.

-

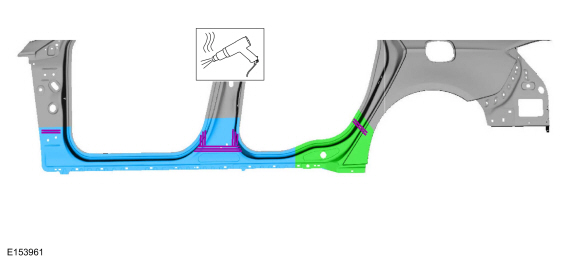

Drill out the spot welds from rocker panel.

Use the General Equipment: Spot Weld Drill Bit

|

-

Break the adhesive bond and remove the outer rocker panel section.

Use the General Equipment: Hot Air Gun

|

Installation

-

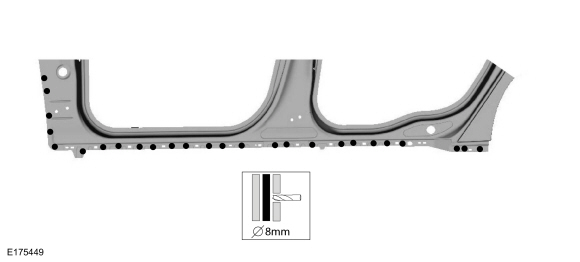

Drill plug weld holes in the replacement rocker panel.

Use the General Equipment: 8 mm Drill Bit

|

-

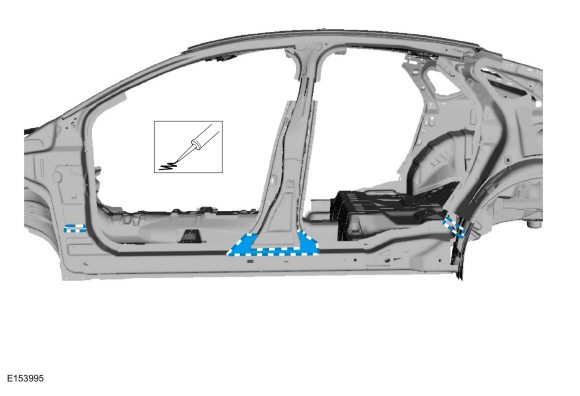

Apply adhesive as indicated.

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B

|

-

Install, clamp and weld the replacement rocker panel.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: Locking Pliers

|

-

Seam and plug weld the rocker panel.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Finish all joints using typical metal finishing techniques.

-

Sand and prime repair area using a Ford approved paint system.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish the repair area using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition the carpeting and the wiring harness.

-

Install the following items:

Refer to: Rocker Panel Moulding (501-08 Exterior Trim and Ornamentation, Removal and Installation).

Refer to: Fender (501-02 Front End Body Panels, Removal and Installation).

Refer to: A-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: B-Pillar Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: C-Pillar Lower Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

Refer to: Front Door (501-03 Body Closures, Removal and Installation).

Refer to: Rear Door (501-03 Body Closures, Removal and Installation).

-

Align the doors.

Refer to: Front Door Alignment (501-03 Body Closures, General Procedures).

Refer to: Rear Door Alignment (501-03 Body Closures, General Procedures).

-

Repower the SRS.

Refer to: Supplemental Restraint System (SRS) Depowering and Repowering (501-20B Supplemental Restraint System, General Procedures).

A-Pillar Reinforcement. Removal and Installation

A-Pillar Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery...

Rocker Panel Inner Reinforcement. Removal and Installation

Rocker Panel Inner Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Hot Air Gun

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Metal Bonding AdhesiveTA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B

-

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

WARNING:

Before beginning any service procedu..

Other information:

Ford Fusion 2013–2020 Service Manual: Fuel Tank Filler Pipe. Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation steps. WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in section 100-00 General Information. Failure to follow this instruction may result in serious personal injury. Refer to: Gasoline and Gasoline-Ethanol Fuel Systems Health and Safety Precautions (100-0..

Ford Fusion 2013–2020 Service Manual: Wire Terminal Inspection and Removal. General Procedures

Disconnect WARNING: Before beginning any service procedure in this section, refer to Health and Safety Precautions in section 100-00 General Information. Failure to follow this instruction may result in serious personal injury. Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation). NOTE: To avoid wiring pin (terminal) dama..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Engine

- Cylinder Head. Removal and Installation

- Load Carrying

- New on site

- Most important about car

Parallel Parking

The system detects available parallel parking spaces and steers your vehicle into the space. You control the accelerator, gearshift and brakes. The system visually and audibly guides you into a parallel parking space.

Press the button once to search

for a parking space.

Press the button once to search

for a parking space.

Copyright © 2026 www.fofusion2.com