Ford Fusion: Rear End Sheet Metal Repairs / Rear Lamp Mounting Panel. Removal and Installation

Special Tool(s) / General Equipment

| Hot Air Gun | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Remove the following items.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

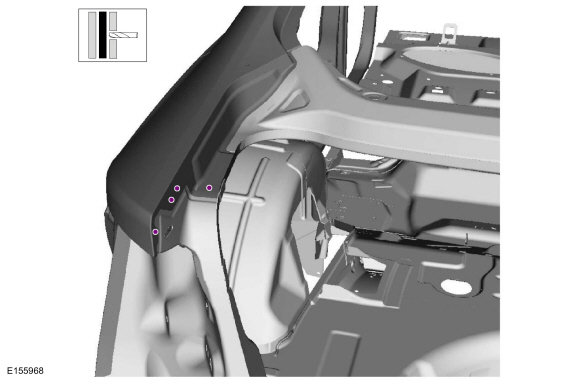

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

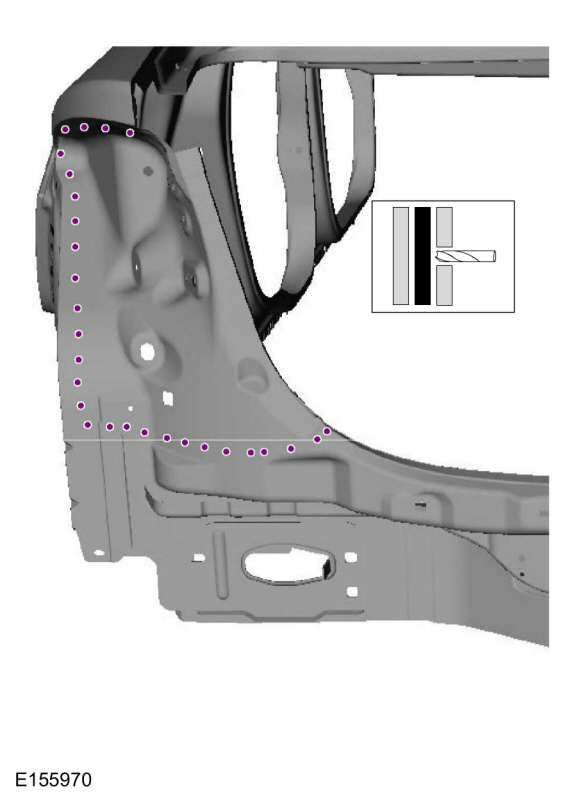

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

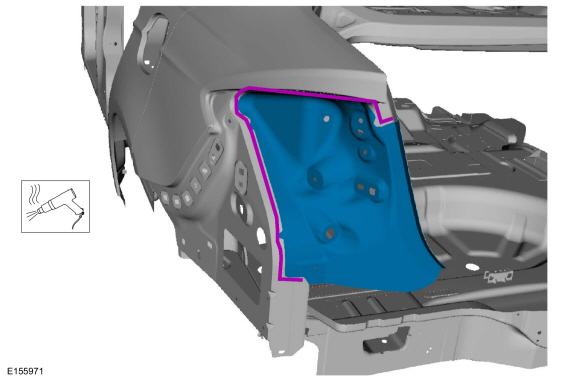

Break the adhesive bond and remove the rear lamp mounting panel.

Use the General Equipment: Hot Air Gun

|

Installation

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

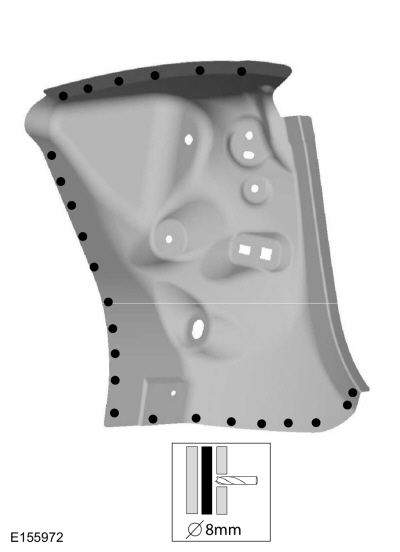

Drill holes in the replacement panel for plug welding.

Use the General Equipment: 8 mm Drill Bit

|

-

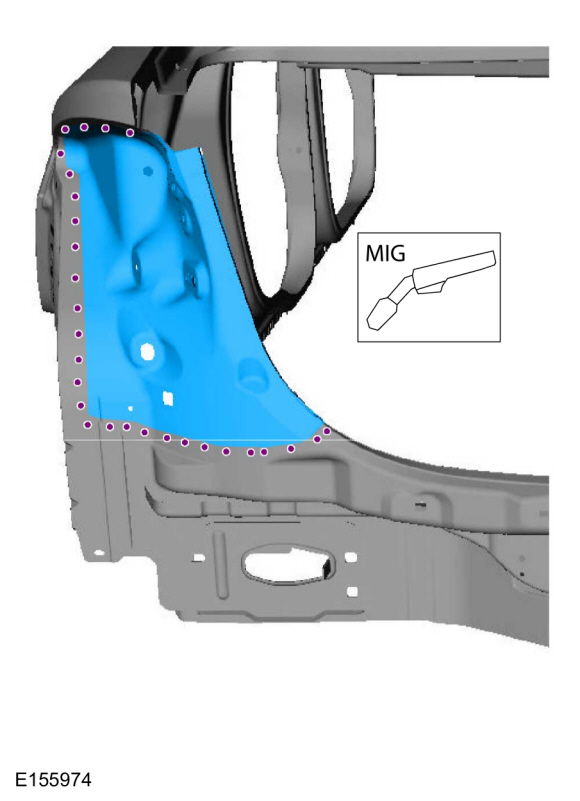

Install the rear lamp mounting panel and plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

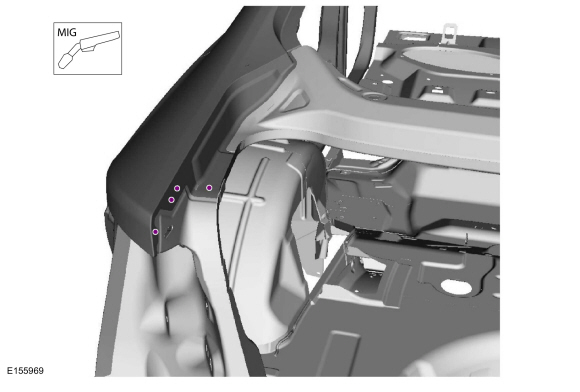

Install plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Finish repair area using typical metal finishing techniques.

-

Sealing work: All areas must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Install the following items.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

Rear Package Tray Panel. Removal and Installation

Rear Package Tray Panel. Removal and Installation

Special Tool(s) /

General Equipment

Resistance Spotwelding Equipment

Scraper for Straight Edges

Hot Air Gun

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (P..

Other information:

Ford Fusion 2013–2020 Service Manual: Tie Rod. Removal and Installation

Special Tool(s) / General Equipment Tie Rod End Remover Tie Rod Remover and Installer Boot Clamp Pliers Materials Name Specification Motorcraft® Premium Long-Life GreaseXG-1-E1 ESA-M1C75-B Removal NOTICE: When servicing inner tie rods, install a new bellows boot and clamps. The boots and clamps are designed to provide an airtight seal and protect t..

Ford Fusion 2013–2020 Service Manual: Pinpoint Test - DTC: J. Diagnosis and Testing

B0070:11, B0070:12, B0070:13 and B0070:1A Refer to Wiring Diagrams Cell 46 for schematic and connector information. Normal Operation and Fault Conditions The RCM continuously monitors the driver seatbelt anchor pretensioner circuits for the following faults: Resistance out of range Unexpected voltage Short to ground Faulted driver seatbelt anchor pretensioner ..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Automatic Transmission - 6-Speed Automatic Transmission – 6F35

- Transmission - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

- Under Hood Overview - 1.5L EcoBoost™, 2.0L EcoBoost™, 2.5L, 2.7L EcoBoost™

- New on site

- Most important about car

Using Seatbelts During Pregnancy

WARNING: Always ride and drive with your seatback upright and properly fasten your seatbelt. Fit the lap portion of the seatbelt snugly and low across the hips. Position the shoulder portion of the seatbelt across your chest. Pregnant women must follow this practice. See the following figure.