Ford Fusion: Rear End Sheet Metal Repairs / Rear Floor Panel Section. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Body and Paint / Body and Paint / Rear End Sheet Metal Repairs / Rear Floor Panel Section. Removal and Installation

Special Tool(s) / General Equipment

| Spherical Cutter | |

| Plasma Cutter | |

| Air Body Saw | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

If required, dimensionally restore the vehicle to a pre-accident condition.

Refer to: Vehicle Specific Body Construction (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

-

Remove the following items.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

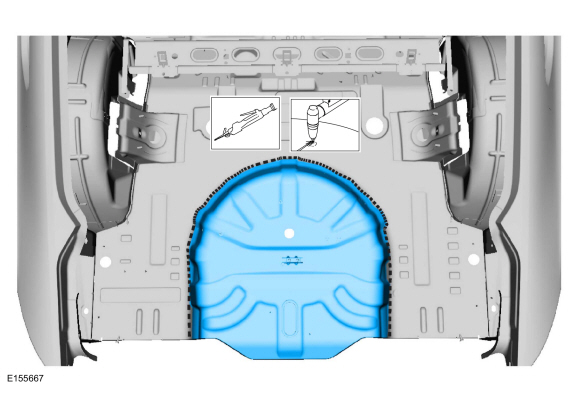

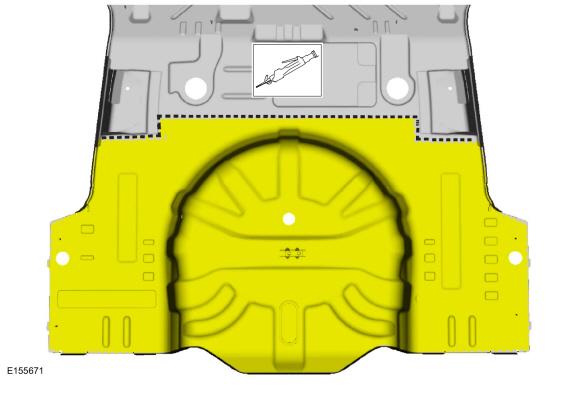

Carefully cut the rear floor panel only as indicated and remove.

Use the General Equipment: Air Body Saw

Use the General Equipment: Plasma Cutter

|

-

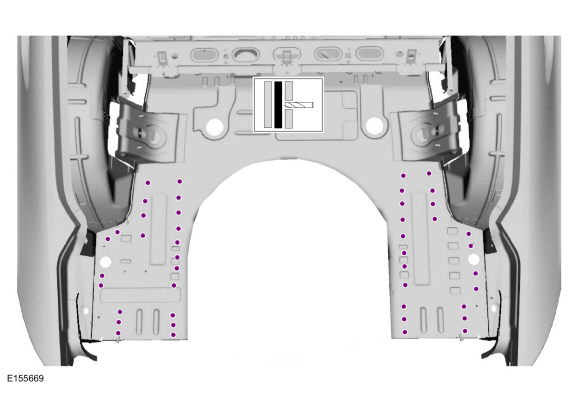

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

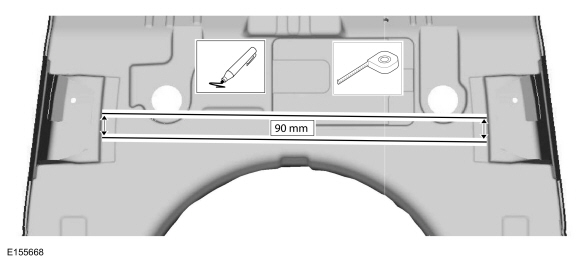

Carefully measure and mark the cut section panel as necessary.

|

-

NOTE: Leave minimum 25.4 mm of existing floor panel along sides of floor for overlap flange.

Carefully cut the rear floor panel and remove.

Use the General Equipment: Plasma Cutter

Use the General Equipment: Spherical Cutter

|

Installation

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Carefully cut the sectioning piece from service part.

Use the General Equipment: Air Body Saw

|

-

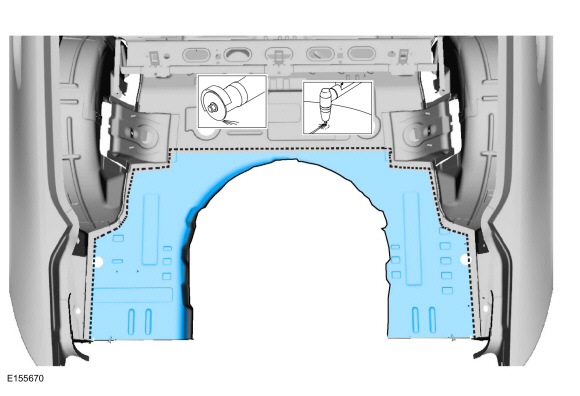

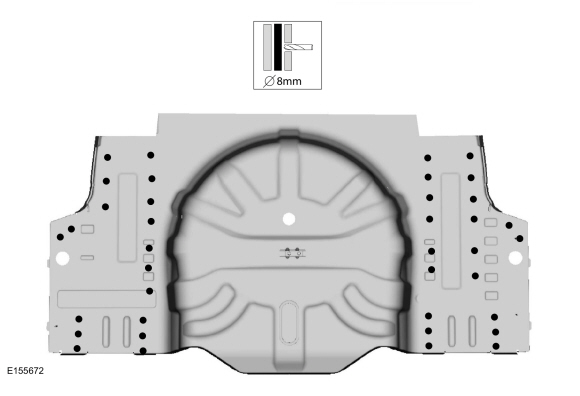

Drill plug welds holes in replacement panel.

Use the General Equipment: 8 mm Drill Bit

|

-

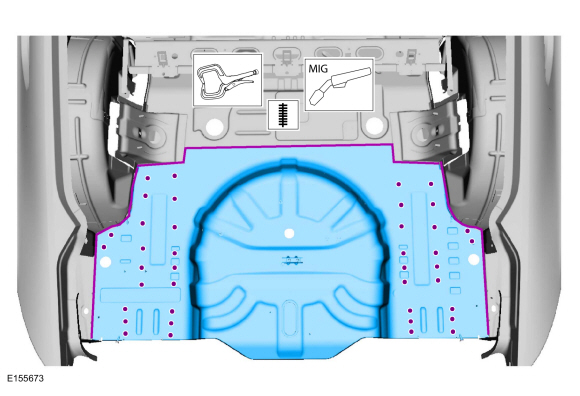

Install the rear floor panel section clamp in position and stitch weld seams and plug weld.

Use the General Equipment: Locking Pliers

Use the General Equipment: MIG/MAG Welding Equipment

|

-

Metal finish as required using typical metal finishing techniques.

-

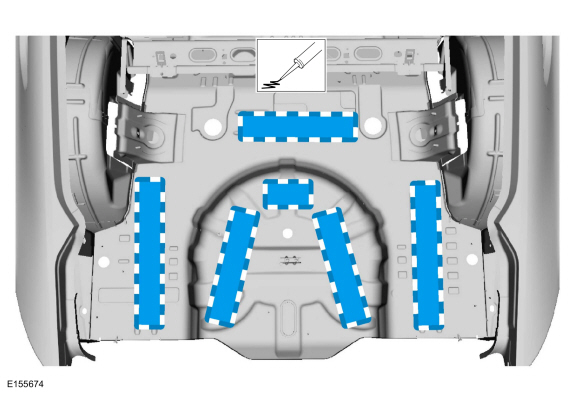

Install butyl mastic NVH pads (obtain locally) in original locations.

|

-

Install the back panel and reinforcement.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Seam sealing: All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a Ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Install the following items.

Refer to: Back Panel and Reinforcement (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Rear Floor Panel Reinforcement. Removal and Installation

Rear Floor Panel Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery...

Rear Lamp Mounting Panel. Removal and Installation

Rear Lamp Mounting Panel. Removal and Installation

Special Tool(s) /

General Equipment

Hot Air Gun

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information...

Other information:

Ford Fusion 2013–2020 Service Manual: Radiator Grille Opening Panel Reinforcement. Removal and Installation

Removal NOTE: Left hand (LH) side shown, right hand (RH) side similar. NOTE: Engine removed for clarity. Overview Remove the hood and prop rod. Refer to: Hood (501-02 Front End Body Panels, Removal and Installation)...

Ford Fusion 2013–2020 Owners Manual: Replacing the Battery

Note: Refer to local regulations when disposing of your remote control batteries. Note: Do not wipe off any grease on the battery terminals or on the back surface of the circuit board. Note: Replacing the battery does not erase the programmed key from your vehicle...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Main Control Valve Body. Removal and Installation

- Transmission - 1.5L EcoBoost (118kW/160PS) – I4. Removal and Installation

- Intake Manifold. Removal and Installation

- New on site

- Most important about car

Power Door Locks

The power door lock control is on the driver and front passenger door panels.

Copyright © 2026 www.fofusion2.com