Ford Fusion: Body Repairs - Vehicle Specific Information and Tolerance Checks / Body Panel Sectioning. General Procedures

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Spherical Cutter | |

| Plasma Cutter | |

| Air Body Saw | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Repair

NOTICE: Do not begin to removal of the vehicle body side until the replacement panel is available for reference.

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, REFER to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, REFER to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Detrim the vehicle as necessary and remove spot welds from the damaged area.

Use the General Equipment: Spot Weld Drill Bit

-

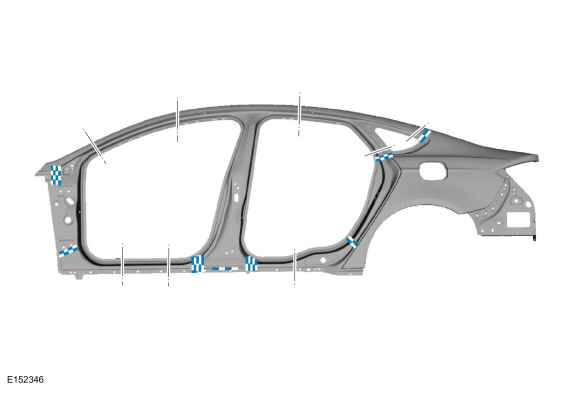

Body side replacement panels are released as 2-part panels. Only remove as much of the body side as necessary.

Refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

Use the General Equipment: Air Body Saw

Use the General Equipment: Plasma Cutter

-

As a general rule, sectioning cut points should be chosen to result in the smallest repair area possible.

Use the General Equipment: Air Body Saw

Use the General Equipment: Plasma Cutter

Use the General Equipment: Spherical Cutter

|

-

NOTE: Use resistance spotwelding equipment where possible. This will produce a higher quality repair.

NOTE: When welding overlapping surfaces or substrates, apply a high quality weld-through primer between the surfaces prior to welding.

Where possible, create a lap-joint backer plate using a portion of the old panel. This will create a stronger joint.

Use the General Equipment: Resistance Spotwelding Equipment

Use the General Equipment: MIG/MAG Welding Equipment

-

Rough finish all sectioning joints with a fibre-based

body filler, final finish sectioning joints and plug welds with a

conventional body filler.

-

Properly seal all horizontal joints to prevent moisture

intrusion. Water and moisture migrate toward horizontal joints and

corrosion tends to occur more rapidly in these areas.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Proceed with the refinishing process using a Ford approved paint system and manufacturers recommendations.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reapply vehicle trim as necessary.

Vehicle Specific Body Construction. Description and Operation

Vehicle Specific Body Construction. Description and Operation

Before cutting or welding, For additional information, refer to: Specifications (501-25 Body Repairs - General Information, Specifications).

Bumper Beams

Bumper

beams are typically constructed of HS (high-strength) or stronger class

steel...

Other information:

Ford Fusion 2013–2020 Service Manual: Ride Height Measurement. General Procedures

Special Tool(s) / General Equipment Surface Gauge Check NOTE: Ride Height Measurement - Front NOTE: Make sure that the vehicle is positioned on a flat, level surface and the tires are inflated to the correct pressure. Vehicle should have a full tank of fuel. Ride height = 3-2 Measurement 2 Measurement 3 Use the General Equipment: Surface Gauge..

Ford Fusion 2013–2020 Service Manual: Engine Cooling - Component Location. Description and Operation

Item Part Number Description 1 81008100 Pressure relief cap 2 8A0808A080 Degas bottle 3 8A3658A365 Degas bottle-to-engine hose 4 60906090 Cylinder head 5 76107610 Cylinder head tube 6 18C26618C266 Heater hose assembly 7 18B53918B539 Heater core 8 7G0717G071 Transmission warmer inlet hose 9 1..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Powertrain

- Engine - 1.5L EcoBoost (118kW/160PS) – I4

- Electronic Parking Brake (EPB) Service Mode Activation and Deactivation. General Procedures

- New on site

- Most important about car

Fuel Quality

Choosing the Right Fuel

Your vehicle is designed to operate on regular unleaded gasoline with a minimum pump (R+M)/2 octane rating of 87.