Ford Fusion: Rear End Sheet Metal Repairs / Back Panel and Reinforcement. Removal and Installation

Special Tool(s) / General Equipment

| Hot Air Gun | |

| 8 mm Drill Bit | |

| MIG/MAG Welding Equipment | |

| Spot Weld Drill Bit | |

| Locking Pliers |

Materials

| Name | Specification |

|---|---|

| Metal Bonding Adhesive TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B |

- |

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Remove the following items. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

Refer to: Rear Lamp Assembly - 4-Door (417-01 Exterior Lighting, Removal and Installation).

-

Remove the luggage compartment trim.

-

Reposition the carpet and wiring harness away from the work area.

-

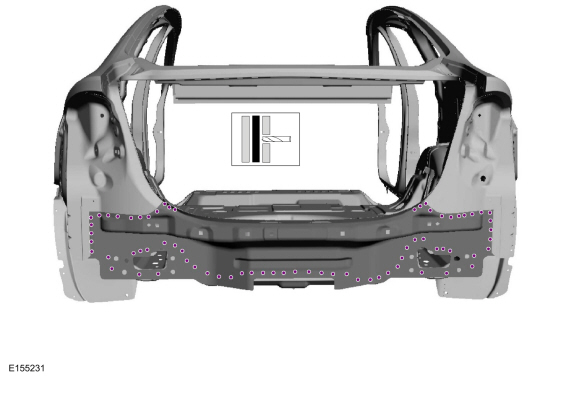

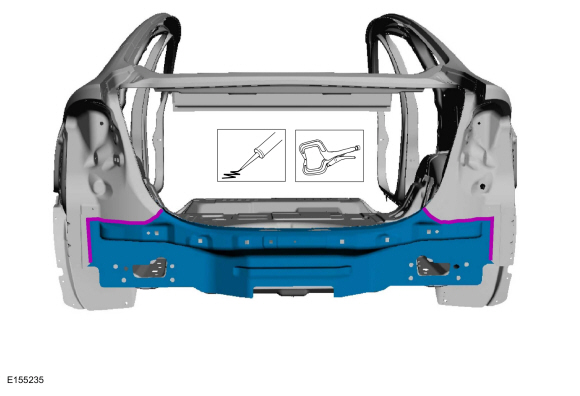

Drill out the spot welds.

Use the General Equipment: Spot Weld Drill Bit

|

-

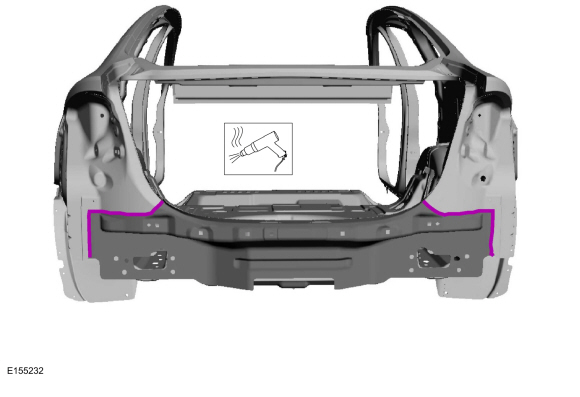

Break the adhesive bond.

Use the General Equipment: Hot Air Gun

|

-

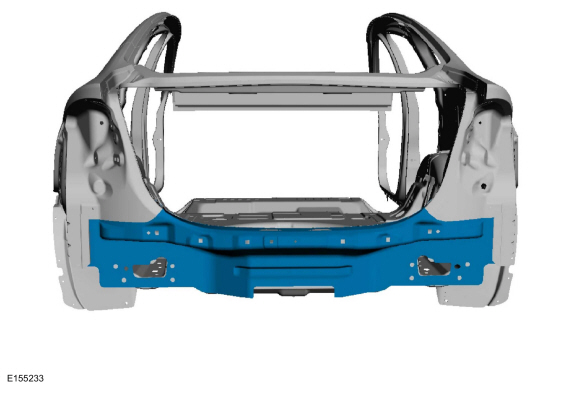

Remove the back panel and reinforcement.

|

Installation

-

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation). WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

-

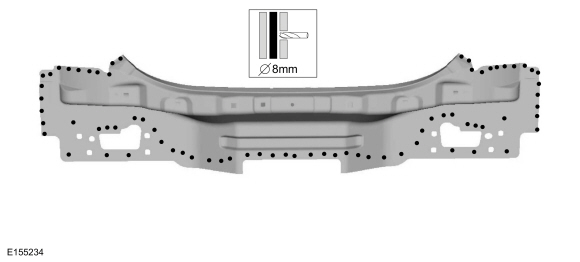

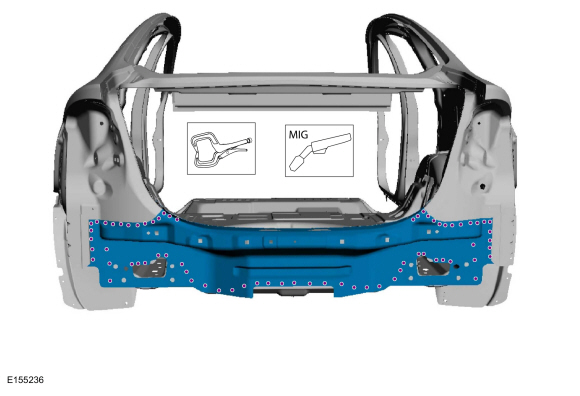

Drill holes in the replacement back panel reinforcement for plug welding.

Use the General Equipment: 8 mm Drill Bit

|

-

Apply the adhesive, install the back panel and reinforcement and clamp in position.

Use the General Equipment: Locking Pliers

Material: Metal Bonding Adhesive / TA-1, TA-1-B, 3M™ 08115, LORD Fusor® 108B

|

-

Install the plug welds.

Use the General Equipment: MIG/MAG Welding Equipment

Use the General Equipment: Locking Pliers

|

-

Finish the repair area using typical metal finishing procedures.

-

Seam sealing: All seams must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using a ford approved paint system.

-

Restore corrosion protection.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

-

Reposition the wiring harness and carpet.

-

Install the following items.

Refer to: Rear Bumper (501-19 Bumpers, Removal and Installation).

Refer to: Rear Lamp Assembly - 4-Door (417-01 Exterior Lighting, Removal and Installation).

Floor Panel Reinforcement. Removal and Installation

Floor Panel Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

Scraper for Straight Edges

Hot Air Gun

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Materials

Name

Specification

Seam SealerTA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electr..

Other information:

Ford Fusion 2013–2020 Owners Manual: Garage Door Opener

HomeLink Wireless Control System WARNING: Do not use the system with any garage door opener that does not have the safety stop and reverse feature as required by U.S. Federal Safety Standards (this includes any garage door opener manufactured before April 1, 1982). A garage door opener which cannot detect an object, signaling the door to stop and reverse, does not meet current federal saf..

Ford Fusion 2013–2020 Owners Manual: Automatic Climate Control - Vehicles With: Sony Audio System/Touchscreen Display

Note: Depending on your vehicle option package, the controls may look different from what you see here. Note: You can switch temperature units between Fahrenheit and Celsius. Setting the Blower Motor Speed Press and release + or - to adjust the volume of air circulated in the vehicle. Setting the Temperature Press and release + or - on the left-hand side of the climate control to set the..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Engine - 1.5L EcoBoost (118kW/160PS) – I4

- Body Control Module (BCM). Removal and Installation

- Memory Function

- New on site

- Most important about car

Parallel Parking

The system detects available parallel parking spaces and steers your vehicle into the space. You control the accelerator, gearshift and brakes. The system visually and audibly guides you into a parallel parking space.

Press the button once to search

for a parking space.

Press the button once to search

for a parking space.