Ford Fusion: Rear End Sheet Metal Repairs / Rear Wheelhouse Outer. Removal and Installation

Ford Fusion 2013–2020 Service Manual / Body and Paint / Body and Paint / Rear End Sheet Metal Repairs / Rear Wheelhouse Outer. Removal and Installation

Special Tool(s) / General Equipment

| Resistance Spotwelding Equipment | |

| Air Body Saw |

Materials

| Name | Specification |

|---|---|

| Seam Sealer TA-2-B, 3M™ 08308, LORD Fusor® 803DTM |

- |

Removal

-

Follow the health and safety precautions. WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

WARNING:

Before beginning any service procedure in this

section, refer to Safety Warnings in section 100-00 General Information.

Failure to follow this instruction may result in serious personal

injury.

Refer to: Health and Safety Precautions (100-00 General Information, Description and Operation).

-

Remove the following items.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

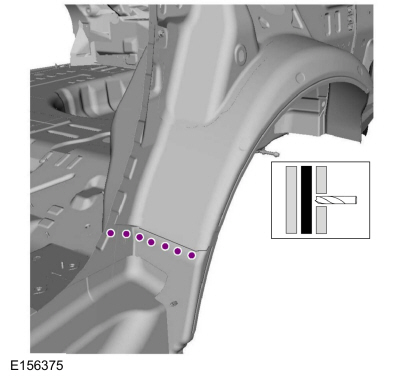

Drill out the spot welds.

|

-

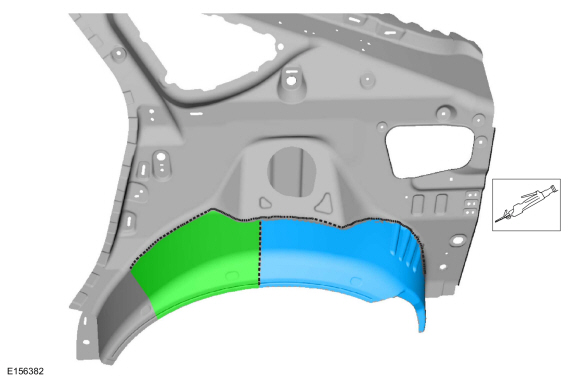

Carefully cut the rear wheelhouse outer panel only and remove.

|

-

A residual flange in the joining area of approximately

12 mm is needed for welding in the components with an overlap.

Use the General Equipment: Air Body Saw

Installation

-

Cut repair panel so that it will overlap by approximately 12 mm in the joining area.

-

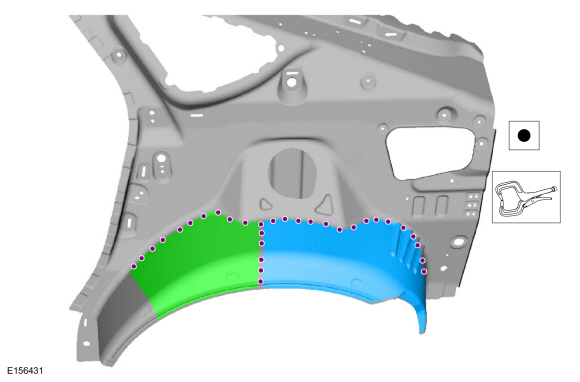

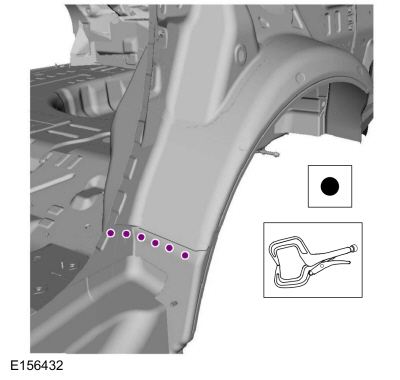

Install the rear wheelhouse outer panel, clamp in position and spot weld.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Install the spot welds.

Use the General Equipment: Resistance Spotwelding Equipment

|

-

Finish the repair area using typical metal finishing procedures.

-

Sealing work: All ares must be sealed to production level.

Material: Seam Sealer / TA-2-B, 3M™ 08308, LORD Fusor® 803DTM

-

Refinish using Ford approved paint system.

-

Install the LH quarter panel.

Refer to: Quarter Panel LH (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

-

Restore the corrosion prevention.

Refer to: Corrosion Prevention (501-25 Body Repairs - General Information, General Procedures).

Rear Suspension Bracket Reinforcement. Removal and Installation

Rear Suspension Bracket Reinforcement. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery...

Spare Tire Bracket. Removal and Installation

Spare Tire Bracket. Removal and Installation

Special Tool(s) /

General Equipment

8 mm Drill Bit

MIG/MAG Welding Equipment

Spot Weld Drill Bit

Locking Pliers

Removal

NOTICE:

Battery electric vehicle (BEV), hybrid electric vehicle

(HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage

battery...

Other information:

Ford Fusion 2013–2020 Service Manual: Engine Cooling System Draining, Vacuum Filling and Bleeding. General Procedures

Special Tool(s) / General Equipment ROB75240Coolant/Battery Refractometer (Fahrenheit) Fluid Container Cooling System Vacuum Tester and Refiller Draining NOTICE: The coolant must be recovered in a suitable, clean container for reuse...

Ford Fusion 2013–2020 Service Manual: Engine Cooling - System Operation and Component Description. Description and Operation

System Operation Engine coolant flows primarily from the engine to the radiator circuit and back to the coolant pump. Coolant is sent from the coolant pump through the engine block and cylinder head. A separate circuit from the engine also feeds the heater core and turbocharger with coolant...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Body Control Module (BCM). Removal and Installation

- Electrical

- Starter Motor. Removal and Installation

- New on site

- Most important about car

Manual Climate Control

Note: Depending on your vehicle option package, the controls may look different from what you see here.

Copyright © 2026 www.fofusion2.com