Ford Fusion: Automatic Transmission - 6-Speed Automatic Transmission – 6F35 / Leakage Inspection. Diagnosis and Testing

Ford Fusion 2013–2020 Service Manual / Powertrain / Automatic Transmission / Automatic Transmission - 6-Speed Automatic Transmission – 6F35 / Leakage Inspection. Diagnosis and Testing

Leak Check Test

-

With the vehicle in NEUTRAL, position the vehicle on a hoist.

REFER to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

Inspect the gasket and sealing areas for evidence of leakage.

-

Trace the transmission fluid leak to the highest point.

-

Clean area of suspected leak.

-

Lower vehicle.

-

Remove the transmission fluid fill plug.

-

Add leak detection dye to the transmission fluid. Use 1 fl oz

(30 ml) of dye solution for every 4 qt (3.8 L) of transmission fluid.

-

Road test the vehicle for at least 1 mile with at least 1 application of the TCC.

-

With the vehicle in NEUTRAL, position the vehicle on a hoist.

REFER to: Jacking and Lifting - Overview (100-02 Jacking and Lifting, Description and Operation).

-

If the source of the leak is obvious, repair as required.

-

After the repair, clean the affected area.

Leakage From Torque Converter Housing

Add leak detection dye 1 fl oz ( 30 ml) of dye solution for every 4 qt ( 3.8 L) of transmission fluid.

-

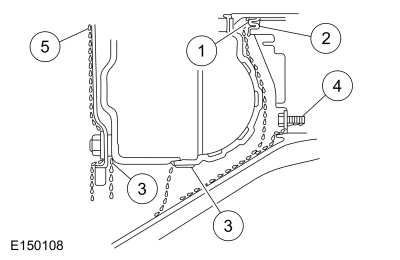

Leaks from the torque converter housing can originate from

several locations. The paths which the transmission fluid takes to reach

the bottom of the torque converter housing is shown in the

illustration. The 5 following steps correspond with the numbers in the

illustration.

-

Transmission fluid leaking by the converter hub seal lip

will tend to move along the drive hub and onto the back of the torque

converter. Except in the case of a total seal failure, transmission

fluid leakage by the lip of the seal will be deposited on the inside of

the torque converter housing only, near the outside diameter of the

housing.

-

Transmission fluid leakage by the outside diameter of the

torque converter impeller hub seal and the case will follow the same

path that leaks by the inside diameter of the converter hub seal follow.

-

Transmission fluid leakage from the converter cover weld or

the converter-to-flexplate stud weld will appear at outside diameter of

torque converter on the back face of the flexplate and in the converter

housing only near the flexplate. If a converter-to-flexplate lug, lug

weld or converter cover weld leak is suspected, remove the converter and

pressure check.

-

Transmission fluid leakage from the bolts inside the

converter housing will flow down the back of the torque converter

housing. Leakage may be from loose or missing bolts.

-

Engine oil leaks from the rear main oil.

-

Transmission fluid leaking by the converter hub seal lip

will tend to move along the drive hub and onto the back of the torque

converter. Except in the case of a total seal failure, transmission

fluid leakage by the lip of the seal will be deposited on the inside of

the torque converter housing only, near the outside diameter of the

housing.

-

Remove the torque converter.

-

Using a black light, observe the torque converter housing.

Inspect for evidence of dye from the pump bolts, pump seal, and torque

converter hub seal. Repair as required.

-

If the source of the leak is not evident, continue with this procedure to leak test the torque converter.

-

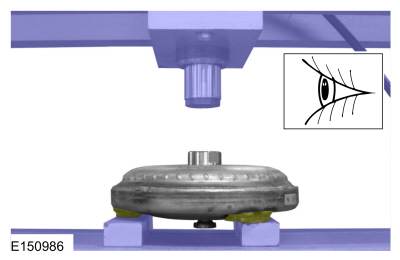

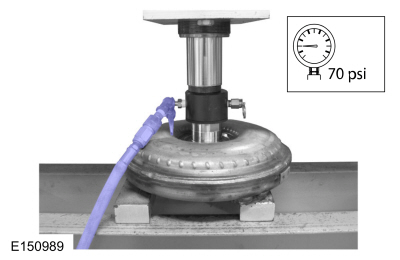

Place the torque converter in an arbor press. Support the torque converter on the mounting pads.

-

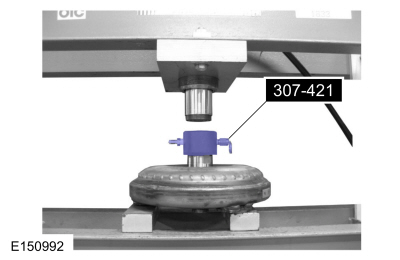

Install the torque converter leak tester (307-421) into the torque converter hub.

-

Secure the press. Apply enough force from the press to seal the

torque converter leak tester (307-421) into the torque converter hub.

-

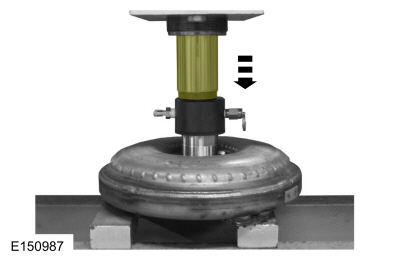

Connect a compressed air supply to the torque converter leak tester (307-421).

-

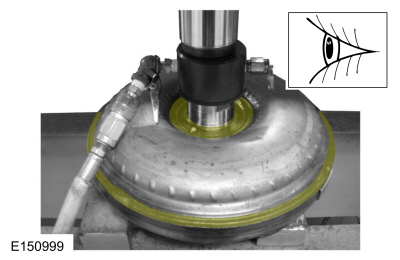

Inspect for leaks at the torque converter hub weld and seams

with air pressure applied to the valve. A soap bubble solution can be

applied around those areas to aid in the diagnosis. If any leaks are

present, install a new torque converter.

-

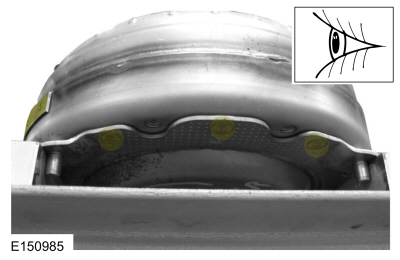

Inspect for leaks at the stud or mounting pad and balance weight

welds. A soap bubble solution can be applied around those areas to aid

in the diagnosis. If any leaks are present, install a new torque

converter.

-

After leaks are repaired, clean the remaining transmission fluid dye from serviced areas.

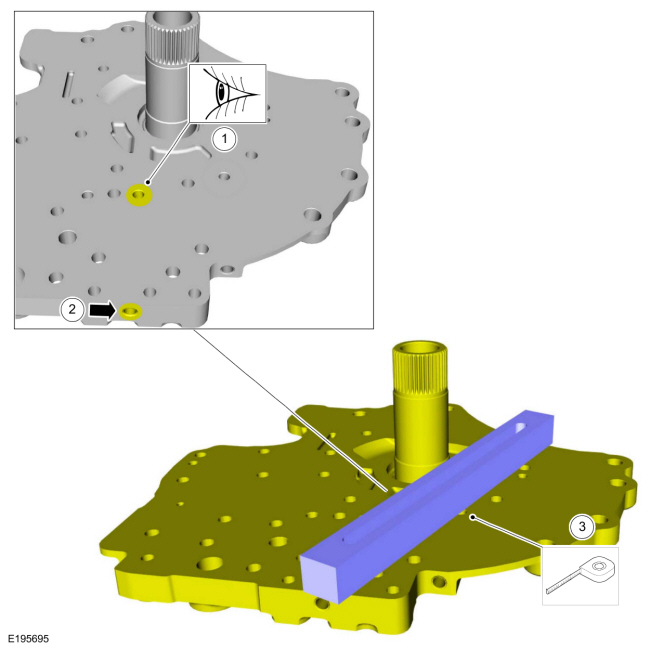

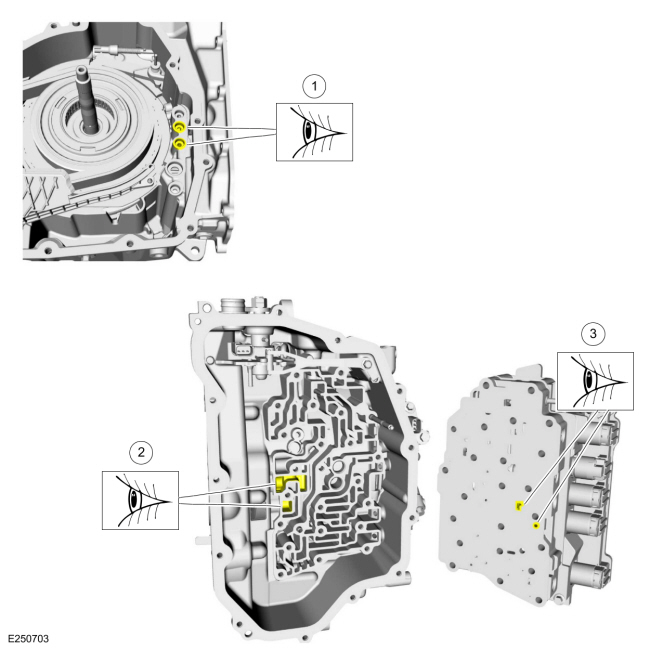

TCC Hydraulic Circuit Leak Paths

-

-

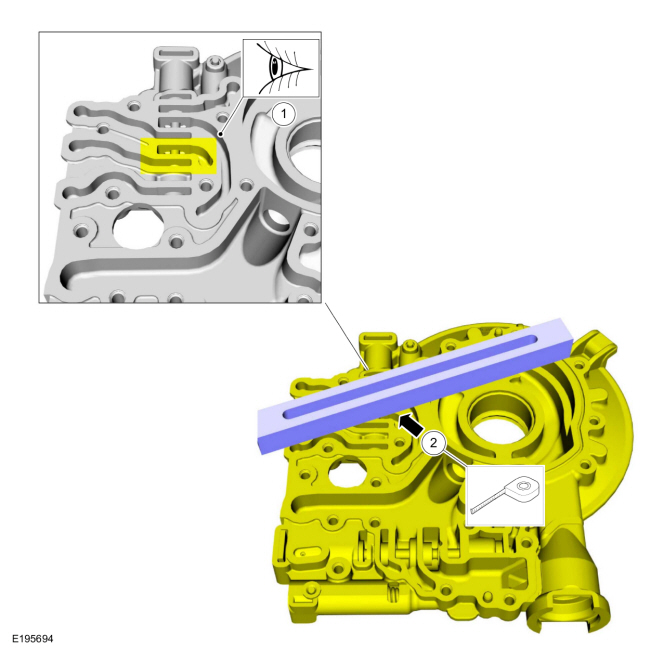

Inspect the aluminum pump housing near the TCC control valve for scoring or blockage.

-

Using a straight edge, inspect the aluminum pump housing near the TCC

control valve for evidence of any surface warping possibly causing

internal pressure leaks. Inspect the hydraulic passages for blockage.

-

Inspect the aluminum pump housing near the TCC control valve for scoring or blockage.

-

-

Inspect the stator support hydraulic passage for scoring or blockage.

-

Inspect the stator support cup plug and verify that it is installed correctly and not loose or missing.

-

Using a straight edge, inspect the stator support

hydraulic passage for evidence of any surface warping possibly causing

internal pressure leaks. Inspect the hydraulic passages for blockage.

-

Inspect the stator support hydraulic passage for scoring or blockage.

-

-

Inspect the pump to transmission case hydraulic passages and seals.

-

Inspect the transmission case to main control hydraulic passages.

-

Inspect the main control hydraulic passages.

-

Inspect the pump to transmission case hydraulic passages and seals.

-

-

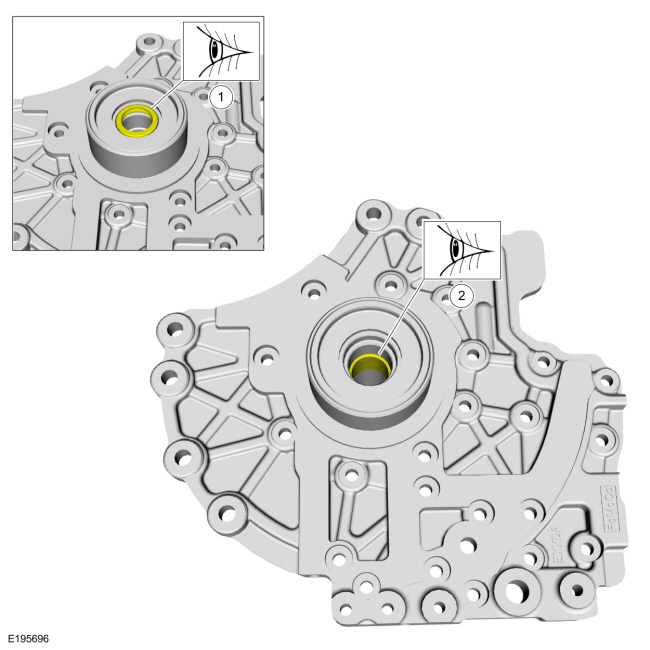

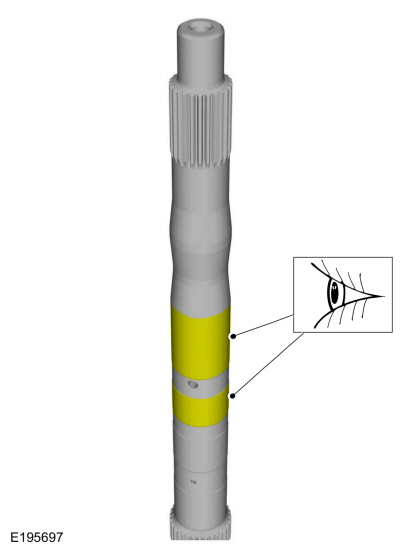

Inspect the turbine shaft oil seal on the stator support for wear or damage that would cause leaks.

-

Inspect the turbine shaft support bushing for wear or scoring that might cause pressure leaks.

-

Inspect the turbine shaft oil seal on the stator support for wear or damage that would cause leaks.

-

Inspect the turbine shaft seal and shaft support bushing

sealing surfaces on the turbine shaft for wear or scoring that might

cause pressure leaks.

Diagnostic Strategy. Diagnosis and Testing

Diagnostic Strategy. Diagnosis and Testing

Overview

The

diagnostic process for each transmission concern will vary depending on

the symptoms and condition of the vehicle. The diagnostic process

below is an efficient method to collect as much data as possible about

the concern before performing a repair or removing the transmission from

the vehicle for teardown and further inspection...

Parameter Identification (PID) Chart. Diagnosis and Testing

Parameter Identification (PID) Chart. Diagnosis and Testing

Diagnostic PID Chart

PID Acronym

PID Name

Description

APP1

APP sensor 1

APP

AST

Time Since Start

Time (in seconds) since the vehicle was started

CLRDIST

Distance since DTC cleared

Distance driven since PCM Diagnostic Trouble Codes (DTCs) were cleared

DTC PCM

Continuous Co..

Other information:

Ford Fusion 2013–2020 Owners Manual: Anti-Theft Alarm

The system will warn you of an unauthorized entry to your vehicle. It will be triggered if any door, the luggage compartment or the hood is opened without using the key, remote control or keyless entry keypad. The direction indicators will flash and the horn will sound if unauthorized entry is attempted while the alarm is armed. Take all remote controls to an authorized dealer if there is ..

Ford Fusion 2013–2020 Service Manual: Climate Control Housing - Vehicles With: Electronic Manual Temperature Control (EMTC). Removal and Installation

Removal NOTE: Removal steps in this procedure may contain installation details. Remove the instrument panel upper section. Refer to: Instrument Panel Upper Section (501-12 Instrument Panel and Console, Removal and Installation). Detach the wiring harness retainer, remove the nuts and the instrument panel upper brace. Torque: 133 lb.in (15 Nm) ..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Automatic Transmission Fluid Check - 1.5L EcoBoost™/2.0L EcoBoost™/2.5L. Automatic Transmission Fluid Check - 2.7L EcoBoost™

- Under Hood Overview - 1.5L EcoBoost™, 2.0L EcoBoost™, 2.5L, 2.7L EcoBoost™

- Main Control Valve Body. Removal and Installation

- New on site

- Most important about car

Manual Climate Control

Note: Depending on your vehicle option package, the controls may look different from what you see here.

Copyright © 2026 www.fofusion2.com