Ford Fusion: Engine System - General Information / Cylinder Block Distortion. General Procedures

Ford Fusion 2013–2020 Service Manual / Powertrain / Engine / Engine System - General Information / Cylinder Block Distortion. General Procedures

Special Tool(s) / General Equipment

| Feeler Gauge |

Check

NOTE: Refer to the appropriate Section 303-01 for the specification.

-

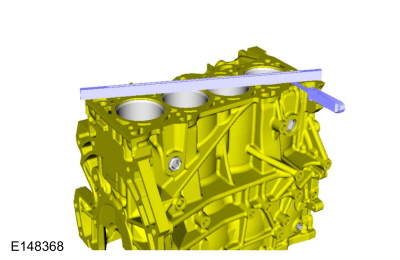

NOTE: Use a Straightedge that is calibrated by the manufacturer to be flat within 0.005 mm (0.0002 in) per running foot of length, such as Snap-On® GA438A or equivalent. For example, if the Straightedge is 61 cm (24 in) long, the machined edge must be flat within 0.010 mm (0.0004 in) from end to end.

Use a Straightedge and a Feeler Gauge Set to inspect the cylinder block for flatness.

Use the General Equipment: Feeler Gauge

|

Cylinder Block Core Plug Replacement. General Procedures

Cylinder Block Core Plug Replacement. General Procedures

Special Tool(s) /

General Equipment

100-001

(T50T-100-A)

Slide Hammer

Materials

Name

Specification

Motorcraft® Threadlock 262TA-26

WSK-M2G351-A6

Repair

All core plugs

NOTE:

Cylinder block core plug shown, cylinder head core plug similar...

Cylinder Bore Taper. General Procedures

Cylinder Bore Taper. General Procedures

Check

NOTE:

Refer to the appropriate Section 303-01 for the specification.

Measure the cylinder bore at the top, middle and bottom

of piston ring travel in 2 directions as indicated...

Other information:

Ford Fusion 2013–2020 Service Manual: Roof Front Frame. Removal and Installation

Special Tool(s) / General Equipment Resistance Spotwelding Equipment Spot Weld Drill Bit Locking Pliers Removal NOTICE: Battery electric vehicle (BEV), hybrid electric vehicle (HEV) and plug-in hybrid electric vehicle (PHEV) contain a high-voltage battery...

Ford Fusion 2013–2020 Service Manual: Front Door Latch. Removal and Installation

Removal NOTE: LH side shown, RH side similar. NOTE: Removal steps in this procedure may contain installation details. Remove the front door window regulator. Refer to: Front Door Window Regulator (501-11 Glass, Frames and Mechanisms, Removal and Installation)...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Garage Door Opener

- Engine

- Electrical

- New on site

- Most important about car

Child Safety Locks

When these locks are set, the rear doors cannot be opened from the inside.

Copyright © 2026 www.fofusion2.com