Ford Fusion: Hydraulic Brake Actuation / Brake Master Cylinder. Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

All vehicles

-

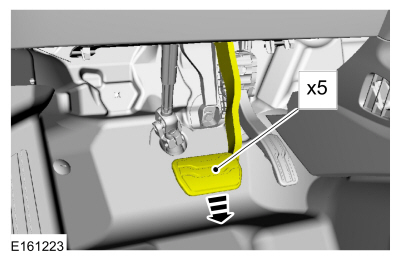

NOTICE: Before removing the master cylinder, relieve the vacuum in the brake booster or the master cylinder O-ring seal may be drawn into the brake booster, causing brake booster failure and increased brake pedal effort.

Fully apply and release the brake pedal 5 times.

|

-

Disconnect the battery.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

1.5L EcoBoost (118kW/160PS)/2.5L Duratec (125kW/170PS)

-

Disconnect the brake fluid level sensor electrical connector and detach the brake tube retainer.

|

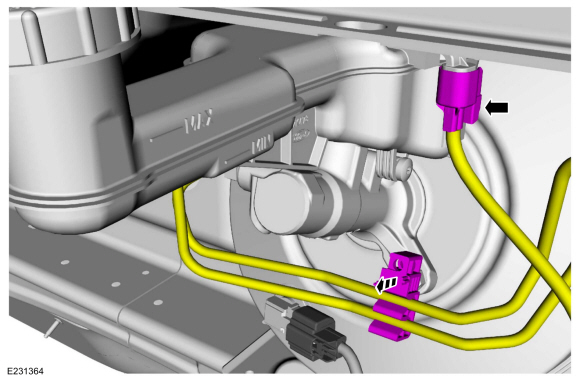

2.0L EcoBoost (184kW/250PS) - MI4/2.7L EcoBoost (238kW/324PS)

-

Disconnect the brake fluid level sensor electrical connector and detach the wiring retainers.

Torque: 18 lb.ft (25 Nm)

|

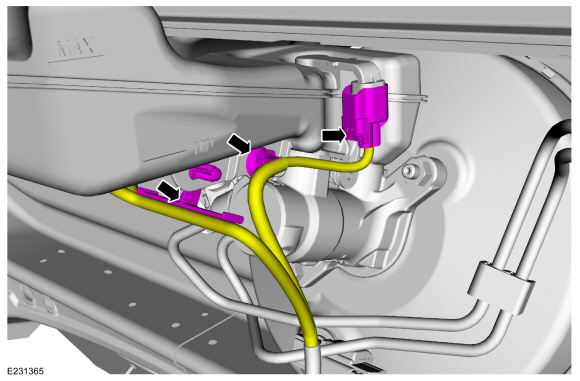

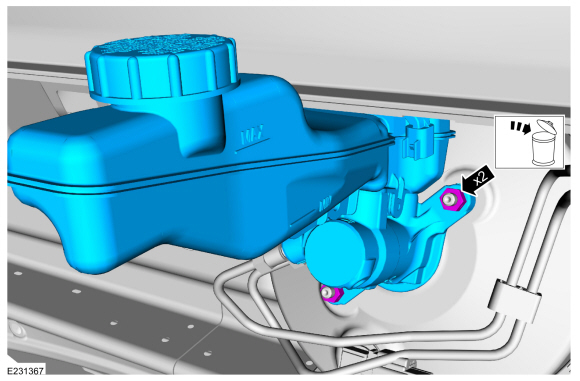

All vehicles

NOTE: 2.0L EcoBoost engine shown

-

NOTICE: If the brake fluid is spilled on the paintwork, the affected area must be immediately washed down with cold water.

NOTICE: Make sure that all openings are sealed.

Disconnect the brake tube fittings.

Torque: 18 lb.ft (25 Nm)

|

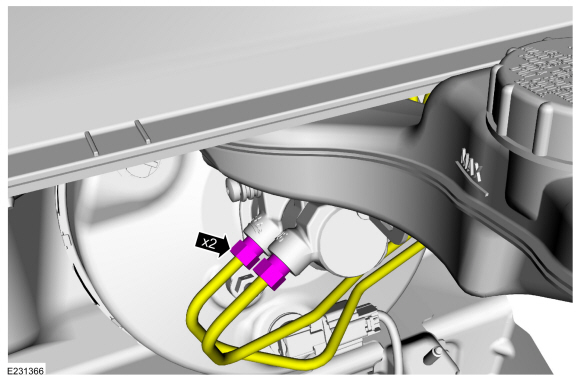

-

NOTE: Make sure that the master cylinder-to-booster seal is removed with the master cylinder.

Remove the nuts and the brake master cylinder. Discard the nuts.

Torque: 18 lb.ft (25 Nm)

|

Installation

-

To install, reverse the removal procedure.

-

-

If a new brake master cylinder has been installed, bleed the master cylinder.

Refer to: Component Bleeding (206-00 Brake System - General Information, General Procedures).

-

If the brake master cylinder was removed to access other components, bleed the brake system.

Refer to: Brake System Pressure Bleeding (206-00 Brake System - General Information, General Procedures).

-

If a new brake master cylinder has been installed, bleed the master cylinder.

Brake Fluid Reservoir. Removal and Installation

Brake Fluid Reservoir. Removal and Installation

Materials

Name

Specification

Motorcraft® DOT 4 LV High Performance Motor Vehicle Brake FluidPM-20

WSS-M6C65-A2

Removal

NOTICE:

If the brake fluid is spilled on the paintwork, the affected area must be immediately washed down with cold water...

Brake Pedal and Bracket. Removal and Installation

Brake Pedal and Bracket. Removal and Installation

Removal

NOTE:

Removal steps in this procedure may contain installation details.

NOTICE:

Do not service the brake pedal or brake booster

without first removing the stoplamp switch...

Other information:

Ford Fusion 2013–2020 Service Manual: Specifications

General Specifications Item Specification 1.5L EcoBoost - 150A (base) Generator pulley ratio 2.42:1 Generator pulley replaceable Yes Generator pulley type Overrunning Alternator Decoupler (OAD) Rating 90 amps at 750 rpm (min) to 155 amps at 2,400 rpm (max) Voltage regulator type..

Ford Fusion 2013–2020 Owners Manual: Remote Start (IF EQUIPPED)

You can switch this feature on or off and adjust the settings using the information display controls. The climate control system adjusts the interior temperature during remote start. You cannot adjust the climate control setting during remote start operation. Switch the ignition on to make adjustments. Based on your remote start settings, the following vehicle-dependent features may or may..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Automatic Transmission - 6-Speed Automatic Transmission – 6F35

- Cylinder Head. Removal and Installation

- Front Controls Interface Module (FCIM). Removal and Installation

- New on site

- Most important about car

Direction Indicators. Interior Lamps

Direction Indicators

Push the lever up or down to use the direction indicators.