Ford Fusion: Climate Control System - General Information / Air Conditioning (A/C) System Leak Test Using Forming Gas. General Procedures

Special Tool(s) / General Equipment

| Forming Gas Pressure Gauge and Leak Detector |

Materials

| Name | Specification |

|---|---|

| Forming Gas | - |

Leak detection

All vehicles

-

NOTE: Use a Rotunda-approved Tracer Gas A/C System Dealership Leak Detection Service Kit that meets SAE J2790.

Recover the refrigerant. Refer to the appropriate Recovery procedure in Group 412.

Hybrid\Electric vehicles

-

Electric or Hybrid vehicle with a battery chiller.

It may be necessary to activate the battery chiller(s) to open the

solenoid(s) to allow vacuum and gas to pass through to chiller for leak

testing. Refer to shop manual refrigerant reclaim and charging to see if

solenoid(s) activation is necessary. Follow the shop manual procedure

to perform activation if needed.

All vehicles

-

Perform the vacuum leak test in accordance with the service unit manufacturer instructions.

-

Assemble tracer gas leak detection kit per manufacturer instructions.

-

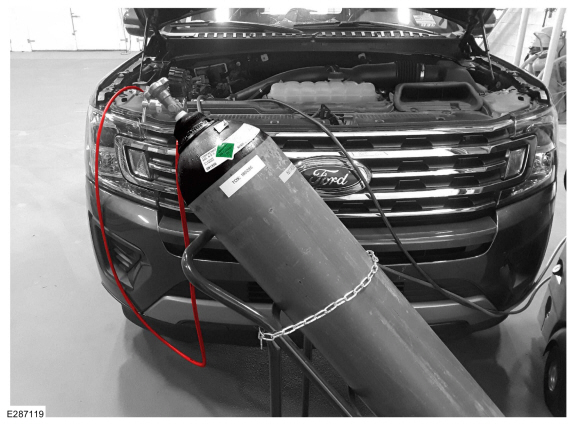

Connect the forming gas pressure gauge and leak

detector service hose to the high-pressure port of the air conditioning

system in accordance with the manufacturer instructions.

Use the General Equipment: Forming Gas Pressure Gauge and Leak Detector

Material: Forming Gas

|

-

NOTICE: Make sure that the pressure reducer (2) is closed.

-

Open the bottle valve.

-

Slowly turn the pressure reducer until a

pressure of 4.1 bar (60 psi) is reached. Maintain open for 30 seconds to

allow tracer gas to fill system.

-

Close the bottle valve.

-

Model D740KIT - Tracer Gas A\C System Dealership Leak Detection Service Kit

-

Open the bottle valve.

|

-

Leak test the refrigerant system. Follow the

instructions included with the Leak Detector for handling and operation

techniques.

-

D740 H2/N2 leak detector

-

D740 H2/N2 leak detector

-

NOTE: Trace gas is lighter than air, and tends to move up from the source of the leak. It is possible that a leak may not be detected if the leak detector tip is held below the leaking fitting, line or component. Always be sure to thoroughly leak test below, above and around the fitting, line or component.

Disconnect the forming gas pressure gauge and leak detector from the air conditioning system in accordance with the manufacturer instructions.

-

NOTICE: Do not ever recover the tracer gas into the A/C recovery/charging machine.

NOTE: Discharge the H2/N2 tracer gas into the atmosphere after the system leak/s are located.

Charge the system with the appropriate refrigerant only after the leak/s are repaired and retested with the H2/N2 tracer gas and the model D740 leak detector. Refer to the appropriate Recharging procedure in Group 412.

Air Conditioning (A/C) System Flushing - Vehicles With: R1234YF Refrigerant. General Procedures

Air Conditioning (A/C) System Flushing - Vehicles With: R1234YF Refrigerant. General Procedures

Special Tool(s) /

General Equipment

Air Conditioning Flush and Purge Service Unit

Air Conditioning Adaptor Kit

Materials

Name

Specification

Motorcraft® A/C System Flushing SolventYN-23

-

Flushing

NOTICE:

Use the Refrigerant Identification Equipment before

recovering any of the vehicle's refrigerant...

Air Conditioning (A/C) System Recovery, Evacuation and Charging - Vehicles With: R1234YF Refrigerant. General Procedures

Air Conditioning (A/C) System Recovery, Evacuation and Charging - Vehicles With: R1234YF Refrigerant. General Procedures

Special Tool(s) /

General Equipment

Air Conditioning Service Unit

Refrigerant Identification Equipment

Recovery

NOTICE:

Use an A/C refrigerant analyzer before recovering any of the vehicle's A/C refrigerant...

Other information:

Ford Fusion 2013–2020 Service Manual: Front Strut and Spring Assembly. Removal and Installation

Removal NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design...

Ford Fusion 2013–2020 Service Manual: Instrument Panel and Interior Switches Illumination - System Operation and Component Description. Description and Operation

System Operation System Diagram Item Description 1 FDIM 2 BCM 3 DDM 4 RDM 5 PDM 6 RDM 7 Headlamp Switch 8 Dimmable Components 9 GWM 10 Non-Dimmable Components 11 Non-Dimmable Components 12 Non-Dimmable Components 13 Non-Dimmable Components 14 Light Sensor 15 FCIM 16 APIM 17 ACM ..

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Automatic Transmission Fluid Check - 1.5L EcoBoost™/2.0L EcoBoost™/2.5L. Automatic Transmission Fluid Check - 2.7L EcoBoost™

- Oil Cooler. Removal and Installation

- Steering Column Control Module (SCCM). Removal and Installation

- New on site

- Most important about car

Parallel Parking

The system detects available parallel parking spaces and steers your vehicle into the space. You control the accelerator, gearshift and brakes. The system visually and audibly guides you into a parallel parking space.

Press the button once to search

for a parking space.

Press the button once to search

for a parking space.