Ford Fusion: Rear Suspension / Toe Link. Removal and Installation

Special Tool(s) / General Equipment

| Vehicle/Axle Stands |

Removal

NOTICE: Suspension fasteners are critical parts that affect the performance of vital components and systems. Failure of these fasteners may result in major service expense. Use the same or equivalent parts if replacement is necessary. Do not use a replacement part of lesser quality or substitute design. Tighten fasteners as specified.

-

Remove the wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires) .

-

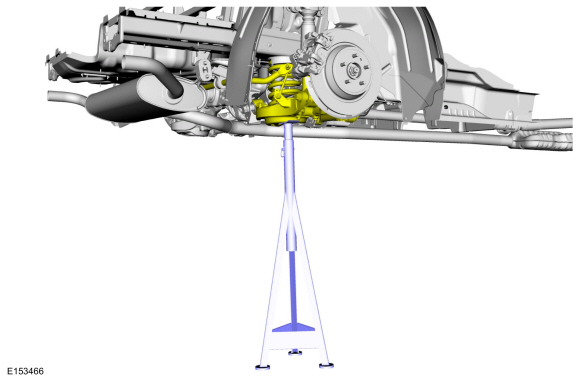

Support the rear suspension to ride height.

Use the General Equipment: Vehicle/Axle Stands

|

-

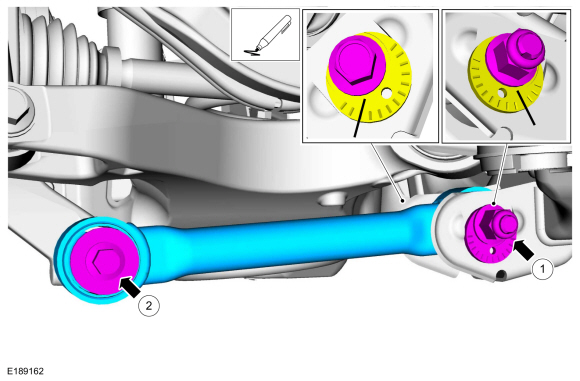

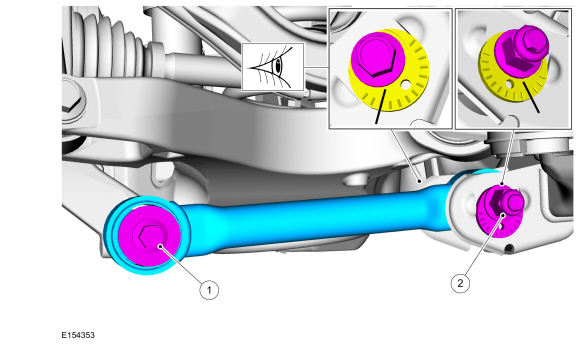

Index mark the cam adjusters for reference during installation.

-

Remove the toe link-to-subframe cam bolt and nut.

-

Remove the toe link-to-wheel knuckle bolt.

-

Remove the toe link-to-subframe cam bolt and nut.

|

Installation

-

NOTICE: Tighten the suspension bushing fasteners with the suspension loaded or with the weight of the vehicle resting on the wheels and tires, otherwise incorrect clamp load and bushing damage may occur.

Align reference marks made during removal.

-

Install the toe link-to-wheel knuckle bolt.

Torque: 76 lb.ft (103 Nm)

-

Install the toe link-to-subframe cam bolt and nut.

Torque: 129 lb.ft (175 Nm)

-

Install the toe link-to-wheel knuckle bolt.

|

-

Install the wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires) .

-

Check and if necessary adjust rear toe.

Refer to: Rear Toe Adjustment (204-00 Suspension System - General Information, General Procedures).

Wheel Studs. Removal and Installation

Wheel Studs. Removal and Installation

Special Tool(s) /

General Equipment

Hydraulic Press

Removal

Remove the wheel bearing and wheel hub.

Refer to: Wheel Bearing and Wheel Hub - FWD (204-02 Rear Suspension, Removal and Installation)...

Wheel Knuckle - AWD. Removal and Installation

Wheel Knuckle - AWD. Removal and Installation

Special Tool(s) /

General Equipment

Vehicle/Axle Stands

Removal

NOTICE:

Suspension fasteners are critical parts that affect the

performance of vital components and systems...

Other information:

Ford Fusion 2013–2020 Service Manual: Instrument Panel. Removal and Installation

Special Tool(s) / General Equipment Hose Clamp(s) Interior Trim Remover Removal NOTE: Removal steps in this procedure may contain installation details. All vehicles WARNING: Before beginning any service procedure in this section, refer to Safety Warnings in section 100-00 General Information...

Ford Fusion 2013–2020 Owners Manual: Capacities and Specifications - 2.7L EcoBoost™

Use oil and fluid that meets the defined specification and viscosity grade. If you do not use oil and fluid that meets the defined specification and viscosity grade, it could result in: Component damage that your vehicle warranty does not cover...

Categories

- Manuals Home

- 2nd Generation Ford Fusion Owners Manual

- 2nd Generation Ford Fusion Service Manual

- Automatic Transmission Fluid Check - 1.5L EcoBoost™/2.0L EcoBoost™/2.5L. Automatic Transmission Fluid Check - 2.7L EcoBoost™

- Engine

- Starter Motor. Removal and Installation

- New on site

- Most important about car

Understanding Your Tire Pressure Monitoring System

The tire pressure monitoring system measures pressure in your road tires and sends the tire pressure readings to your vehicle. You can view the tire pressure readings through the information display. The low tire pressure warning light will turn on if the tire pressure is significantly low. Once the light is illuminated, your tires are under-inflated and need to be inflated to the manufacturer’s recommended tire pressure. Even if the light turns on and a short time later turns off, your tire pressure still needs to be checked.